China's Leading Supplier of Coated Electrical Wire - Quality Manufacturers

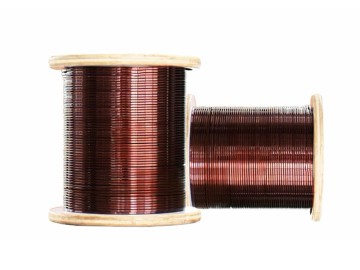

As a premier provider of Paper Coated Electrical Wire, we specialize in meeting the unique needs of manufacturers and factories that demand quality and reliability. Our products adhere to rigorous industry standards, ensuring optimal performance for your electrical applications. With options for bulk orders and long-term supply partnerships, we cater to businesses of all sizes. Our high-quality paper coated wires offer excellent insulation properties, moisture resistance, and durability suitable for a wide range of applications. By partnering with Suzhou Daiming Electrical Materials Co., Ltd., you're choosing a manufacturer that values your satisfaction and supports your business growth. Together, we can enhance your production capabilities with our superior electrical materials.Pinpointing Paper Coated Electrical Wire Sets the Industry Standard Industry Leaders

In the fast-evolving world of electrical materials, the demand for high-quality enameled wires has never been greater. Among the key players setting the industry standard is a manufacturer renowned for its commitment to superior products. By specializing in enameled Aluminum Wires, enameled copper wires, and enameled copper-clad aluminum wires, this company has carved a niche as a trusted provider for global procurement needs. With the integration of advanced technology and innovative production techniques, they ensure their wires meet stringent international standards, crucial for demanding applications in various sectors. The production facility, equipped with 30 state-of-the-art production lines, facilitates a streamlined manufacturing process that supports both scalability and flexibility. This capability allows for customized solutions, catering to diverse requirements while maintaining high-quality output. Buyers can rest assured that each product undergoes rigorous testing and quality control, guaranteeing reliability and performance. As industries increasingly prioritize efficiency and sustainability, the emphasis on superior materials like these enameled wires is paramount, making them the ideal choice for discerning procurement professionals seeking durability and consistency in their supply chains. In conclusion, choosing the right supplier for enameled wires can significantly impact the quality and longevity of your projects. By partnering with industry leaders known for their excellence and innovation, procurement managers can secure superior materials that not only meet but exceed expectations. As the industry continues to evolve, investing in high-quality electrical wires will be a critical factor in staying ahead of the competition and ensuring operational success.

Pinpointing Paper Coated Electrical Wire Sets the Industry Standard

| Dimension | Value |

|---|---|

| Insulation Type | Paper Coated |

| Voltage Rating | 600V |

| Temperature Rating | 90°C |

| Conductor Material | Copper |

| Wire Gauge | 18 AWG |

| Standards Compliance | UL 1015 |

| Applications | Electronics, Automotive |

| Length Options | 100m, 200m, 500m |

| Color Options | Black, Red, Green |

| Market Regions | North America, Europe, Asia |

Key Steps to Choosing Paper Coated Electrical Wire Service Leads the Global Market

B

Benjamin Johnson

The durability of this product is impressive! The customer service was top-tier, addressing every issue I had.

02 July 2025

J

Jacob Wilson

Impressive quality. Their after-sale service team has been very accommodating and knowledgeable.

03 June 2025

G

Grace Thompson

This product is a game changer! The follow-up service was thorough and the representatives were great.

30 May 2025

K

Karen Adams

The durability of this product is impressive. It’s built to last!

01 July 2025

A

Angela Perez

The attention to detail in this product is fantastic. Very well made!

17 July 2025

K

Kyle Torres

The durability of this product is just outstanding. Worth every penny!

29 June 2025