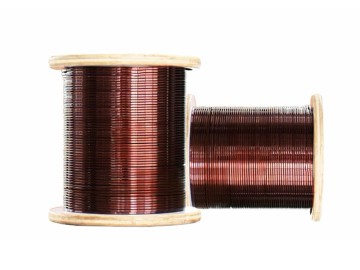

High-Quality Non-Enameled Copper Wire from Trusted Chinese Manufacturers

At Suzhou Daiming Electrical Materials Co., Ltd., we specialize in providing high-quality Non Enameled Copper Wire tailored for manufacturers and wholesalers. Our products are known for their excellent conductivity and durability, making them ideal for a variety of applications. We understand the needs of bulk buyers, which is why we offer competitive pricing while maintaining top-notch quality. Partnering with us ensures a reliable supply source dedicated to supporting B2B customers. Let’s team up to meet your electrical material requirements and enhance the performance of your projects!

10 Essential Tips For Non Enameled Copper Wire Now Trending Custom Solutions,

In today's fast-paced electrical components market, the demand for non-enameled copper wire solutions is on the rise. As a leading manufacturer, Suzhou Daiming Electrical Materials Co., Ltd. recognizes the unique needs of global procurement specialists seeking reliable, high-quality materials. Here are ten essential tips for navigating the landscape of non-enameled copper wire and customizing solutions that fit your specific project requirements. First, understanding the various applications of non-enameled copper wire is crucial. These wires are widely used in industries ranging from telecommunications to automotive, where high conductivity and strength are paramount. Focus on your project's specific needs, such as wire gauge, tensile strength, and environmental factors. Next, consider the benefits of working directly with manufacturers like us, as we can offer tailored solutions that large distributors may not provide. Our 30 state-of-the-art production lines ensure that we can deliver products efficiently while maintaining the highest quality standards. Lastly, prioritize the importance of continuous communication with suppliers. Establishing a solid partnership not only leads to better pricing but also enhances the customization process, enabling us to meet your evolving demands effectively. By leveraging our expertise in Enameled Wires and custom solutions, we can assist you in achieving the optimal outcomes for your projects, ensuring they stand out in this competitive marketplace.

10 Essential Tips For Non Enameled Copper Wire Now Trending Custom Solutions

| Tip Number | Tip Description | Application |

|---|---|---|

| 1 | Choose the right gauge for your needs. | Wiring for electronics. |

| 2 | Ensure proper insulation when necessary. | Automotive applications. |

| 3 | Consider flexibility and bend radius. | Robotics and flexible circuits. |

| 4 | Check for conductivity and resistance. | High-performance applications. |

| 5 | Opt for customized lengths to reduce waste. | Custom electronics projects. |

| 6 | Use appropriate connectors for secure connections. | Home wiring systems. |

| 7 | Maintain a clean working environment. | General assembly and installation. |

| 8 | Use proper tools for cutting and stripping. | Installation and repairs. |

| 9 | Store wires appropriately to avoid tangling. | Workshop and storage solutions. |

| 10 | Monitor for corrosion to maintain performance. | Outdoor and marine applications. |

Comprehensive Comparison of Non Enameled Copper Wire Leads the Global Market Factory

E

Ella Hernandez

Superb product quality! The customer service representatives were both friendly and professional.

05 July 2025

A

Addison Cox

Very satisfied with the quality! The support team was excellent in resolving my queries.

08 June 2025

M

Michael Johnson

Outstanding customer service! The support team was knowledgeable and responsive.

20 May 2025

K

Karen Adams

The durability of this product is impressive. It’s built to last!

01 July 2025

L

Laura Baker

Excellent follow-up service! They truly prioritize customer satisfaction.

05 July 2025

J

Jake Hughes

Satisfaction guaranteed! The product quality speaks for itself.

17 July 2025