High-Quality Enamel Winding Wire Manufacturer from China - Trusted Supplier

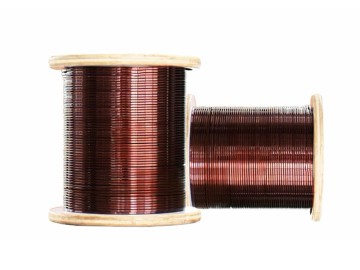

As a trusted supplier of Enamel Winding Wire, we recognize the specific requirements of factories and exporters in today's dynamic market. Our enamel wire is crafted with utmost care to ensure outstanding performance and long-lasting durability, making it suitable for a wide range of applications. We cater to both bulk sourcing and wholesale needs with a focus on flexibility and efficiency. At Suzhou Daiming Electrical Materials Co., Ltd., our dedication to quality and customer satisfaction is unparalleled. Our team collaborates closely with clients to provide customized solutions that enhance productivity and reduce operational costs. Choosing our enamel winding wire guarantees a product that ensures stability and efficiency in your processes. Reach out for competitive pricing and exceptional service that fosters your business growth. Your success is our commitment, and we’re here to support you at every stage.Tips & Tricks for Enamel Winding Wire Ahead of the Curve Sets the Industry Standard

In the fast-evolving world of electrical materials, staying ahead of the curve is essential for businesses looking to maintain a competitive edge. At Suzhou Daiming Electrical Materials Co., Ltd., we recognize the crucial role that high-quality enameled wires play in various applications, from motors to transformers. Our extensive range includes Enameled Aluminum Wires, enameled copper wires, and enameled copper-clad aluminum wires, all produced in our state-of-the-art facility equipped with 30 advanced production lines. When selecting enameled winding wire, several key factors come into play. First, the choice of material can significantly impact performance, especially in high-temperature environments. Enameled copper wires, for instance, offer excellent conductivity and resist corrosion, making them ideal for high-efficiency applications. Conversely, enameled aluminum wires are lighter and generally more cost-effective, which can be advantageous for certain projects. Moreover, attention to wire insulation is paramount. Our enameled wires are designed with superior thermal and electrical insulation properties, ensuring longevity and reliability. By choosing high-quality products from a trusted manufacturer like Suzhou Daiming, global procurement specialists can set a new industry standard, ensuring their end products are not only efficient but also resilient. Embrace innovation and elevate your project quality with our advanced enameled wires—your success is our commitment.

Tips & Tricks for Enamel Winding Wire Ahead of the Curve Sets the Industry Standard

| Dimension | Value | Notes |

|---|---|---|

| Wire Diameter (mm) | 0.8 | Standard gauge for small motors |

| Insulation Type | Polyester | Durable and thermal resistant |

| Tensile Strength (MPa) | 350 | Ensures durability in applications |

| Edging Temperature (°C) | 180 | Maximum temperature for optimal performance |

| Density (g/cm³) | 8.96 | Typical for copper wire |

| Surface Finish | Shiny | Improves conductivity |

| Coating Thickness (µm) | 5 | Enhances electrical insulation |

| Typical Applications | Transformers, Motors | Widely used in electrical devices |

Insider Tips For Enamel Winding Wire Supplies the World’s Top Brands From Concept to Delivery

J

James Worthington

I was impressed by the professional demeanor of the support staff. They took the time to address all my concerns.

18 May 2025

A

Amelia Clark

Amazing product! The after-sales team went above and beyond to ensure my satisfaction.

09 June 2025

H

Henry Anderson

Incredible product quality! The support team was very professional and attentive to my needs.

27 June 2025

E

Elijah King

Impressive product quality, accompanied by professional and friendly after-sale service.

01 June 2025

A

Andrew Rivera

Beyond impressed with the quality! The customer service staff was knowledgeable and responsive.

23 June 2025

A

Anthony Phillips

The team’s professionalism and support were key factors in my repeat business.

29 June 2025