Eaw Coated Electrical Cables: Leading Manufacturers and Factories from China

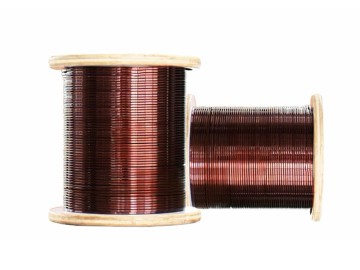

When it comes to sourcing Eaw Coated Electrical Cable, quality and reliability are essential. Our cables are produced in China, adhering to the highest standards to ensure they meet your specifications. With years of experience in exporting, we take pride in offering products that excel in the market. Designed to endure harsh conditions, these cables provide the durability required for your projects. At Suzhou Daiming Electrical Materials Co., Ltd., we focus on understanding our clients’ needs, fostering strong partnerships. We ensure competitive pricing and reliable delivery, helping to keep your operations efficient. Connect with us to discuss how we can effectively support your electrical requirements.

How To Pick The Right Eaw Coated Electrical Cable Dominates Sets the Industry Standard

When selecting the right EAW coated electrical cable, it’s essential to consider several key factors that can significantly impact performance and reliability in your applications. EAW, or Enameled Aluminum Wire, is increasingly becoming the go-to choice due to its lightweight nature and excellent conductivity. However, not all EAW cables are created equal. The choice of materials, insulation quality, and manufacturing standards play crucial roles in determining the longevity and effectiveness of the wires. A leading manufacturer emphasizes the importance of advanced production techniques. State-of-the-art production lines can ensure consistent quality and high performance. It's advisable to inquire about the manufacturing processes used, including the application of the enamel coating—which enhances durability and electrical insulation. Additionally, look for certifications that demonstrate compliance with industry standards, which can provide peace of mind regarding the quality and reliability of the products. Understanding the specific requirements of your applications is also vital. Consider factors such as environmental conditions, operating temperatures, and mechanical stresses that the cables will encounter. Choosing the right EAW coated electrical cable tailored to your particular needs not only ensures operational efficiency but also contributes to safety and cost-effectiveness in the long run. By prioritizing quality and industry standards, you can make an informed decision that supports the success of your projects.

How To Pick The Right EAW Coated Electrical Cable Dominates Sets the Industry Standard

| Cable Type | EAW Coating Material | Temperature Rating (°C) | Voltage Rating (V) | Applications |

|---|---|---|---|---|

| Multi-Core Cable | Polyvinyl Chloride (PVC) | 70 | 600 | Industrial Equipment |

| Single-Core Cable | Cross-Linked Polyethylene (XLPE) | 90 | 1000 | Power Distribution |

| Armoured Cable | Thermoplastic Elastomer (TPE) | 80 | 750 | Construction Sites |

| Flexible Cable | Thermoplastic Polyurethane (TPU) | 70 | 300 | Portable Equipment |

How To Identify Eaw Coated Electrical Cable Winning in 2025 Industry Giant

A

Amelia Clark

Amazing product! The after-sales team went above and beyond to ensure my satisfaction.

09 June 2025

R

Ryan Bell

Quality is unmatched! Their after-sales support team is very expert-driven and helpful.

01 July 2025

M

Maya Bailey

Great craftsmanship! The support staff handled my concerns with utmost professionalism.

18 May 2025

T

Thomas Allen

Impressive expertise from the staff! It really made the purchase easy for me.

14 July 2025

D

David Mitchell

Quick and effective resolutions from their customer service. Highly recommend!

03 July 2025

S

Steven Rogers

Impressive product quality; I can see it lasting for years to come.

17 May 2025