Wholesale Coating Solutions for Electrical Wires - Best Choice for Exporters & Manufacturers

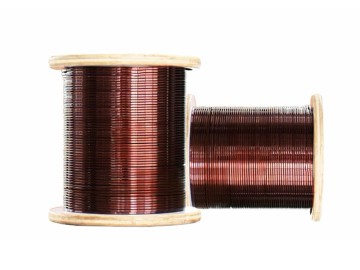

At Suzhou Daiming Electrical Materials Co., Ltd., we provide high-quality Coating On Electrical Wires that enhances durability and resistance for various industrial applications. Our coatings are meticulously crafted to protect wires from environmental challenges while improving performance over time. With rigorous quality controls in place, each batch adheres to industry standards, ensuring reliability for wholesale purchases. We collaborate closely with manufacturers to offer competitive pricing without compromising quality. Whether for bulk supplies in factories or trustworthy solutions for manufacturers, our products are designed to meet diverse needs. Your satisfaction and operational success drive us to deliver excellence in electrical wire coatings. Let's elevate your business together!

Must-See List Coating On Electrical Wires Where Innovation Meets 2025 Dominates

In the ever-evolving world of electrical materials, the demand for high-quality Enameled Wires is accelerating. As we approach 2025, innovation in coating technologies is at the forefront, redefining the standards for enameled aluminum, copper, and copper-clad aluminum wires. These advancements ensure enhanced durability, lower electrical resistance, and significant improvements in thermal insulation, catering to the dynamic needs of various industries including electronics, automotive, and renewable energy. The coating on electrical wires plays a pivotal role in their performance and longevity. Innovative materials are being developed to deliver superior insulation properties, enabling wires to withstand higher temperatures and providing greater resistance to environmental factors. As a result, manufacturers can produce wires that are not only more efficient but also more sustainable, contributing to a greener future. For global purchasers, investing in enameled wire products manufactured using cutting-edge technologies means selecting solutions that are synonymous with quality and reliability. In a market where performance can be the deciding factor, the focus on advanced coatings is crucial. As we look to the future, it is vital to stay ahead of trends that promise to enhance product performance while fulfilling the growing demand for sustainability in electrical materials.

Must-See List Coating On Electrical Wires Where Innovation Meets 2025 Dominates

| Coating Type | Material | Temperature Resistance (°C) | Insulation Voltage (kV) | Application |

|---|---|---|---|---|

| PVC Coating | Polyvinyl Chloride | -10 to 70 | 0.6/1 | General Electrical Wiring |

| XLPE Coating | Cross-linked Polyethylene | -40 to 90 | 12/20 | Industrial Applications |

| Teflon Coating | Polytetrafluoroethylene | -200 to 260 | 0.6/1 | High-Temperature Applications |

| Silicone Coating | Silicone Polymer | -60 to 180 | 1.0/1.5 | Automotive Wiring |

| Rubber Coating | Natural Rubber | -40 to 90 | 0.6/1 | General Purpose Use |

Insider Tips For Coating On Electrical Wires Supplier Guarantees Peak Performance

E

Ella Hernandez

Superb product quality! The customer service representatives were both friendly and professional.

05 July 2025

A

Aria Scott

Loved the product! The customer service was remarkable and very responsive to my questions.

28 June 2025

S

Sarah Williams

I was impressed by the professionalism of the staff. They assisted me every step of the way.

19 May 2025

W

William Wilson

The after-sales support was outstanding! The staff were friendly and helpful.

13 July 2025

J

Jessica Wright

Fantastic service! They went above and beyond to ensure my satisfaction.

03 July 2025

C

Charles Baker

Every interaction with the customer service team was positive and informative.

30 June 2025