Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving landscape of electrical engineering, Eaw Wrapped Wire has emerged as a critical component across various applications, owing to its superior insulation and durability. According to a recent report by the International Wire and Cable Industry Association, the demand for advanced wiring solutions such as Eaw Wrapped Wire is projected to grow by 15% annum through 2025, highlighting its pivotal role in sectors like renewable energy, automotive, and aerospace.

Industry expert Dr. Emily Sharpe has noted, “The use of Eaw Wrapped Wire is revolutionizing the way we approach electrical applications by providing not only enhanced performance but also significant energy efficiency.” This statement underscores the widespread recognition of Eaw Wrapped Wire's benefits, particularly in high-stakes environments where reliability is paramount.

As we delve into the top ten applications and benefits of Eaw Wrapped Wire, it is essential to understand how its unique properties are reshaping industry standards and driving innovation. From improving the longevity of electrical systems to ensuring safety compliance, the importance of Eaw Wrapped Wire cannot be overstated, making it imperative for professionals in the field to stay informed and adapt to these advancements.

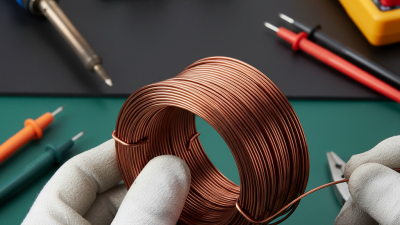

Eaw wrapped wire has become an essential component in electrical engineering due to its unique properties and versatility. This type of wire is characterized by its insulation material, which is wrapped around a conductive core, providing enhanced durability and resistance to environmental factors. One of its primary applications is in transformer windings, where its ability to withstand high temperatures and electrical stress makes it ideal for efficient power distribution.

In addition to transformers, Eaw wrapped wire is also widely used in motor windings and inductors. The design of this wire allows for higher efficiency and reduced energy losses, which is crucial in modern electrical systems. Furthermore, its capacity to minimize electromagnetic interference enhances performance in sensitive applications, such as telecommunications and data processing. The reliability and longevity of Eaw wrapped wire contribute significantly to the overall stability of electrical devices, making it a preferred choice for engineers in a variety of projects.

Eaw wrapped wire has gained significant attention in various industries, primarily due to its enhanced performance and safety features. According to a report by the International Wire and Cable Manufacturers Association, the use of wrapped wire can improve insulation resistance by over 30%, significantly reducing the risk of electrical failure in high-stress environments. This characteristic is crucial in sectors such as aerospace and automotive, where safety and reliability are paramount. Additionally, Eaw wrapped wire's novel construction contributes to lower dielectric losses, which can enhance energy efficiency by up to 25% in electrical applications.

The safety benefits of Eaw wrapped wire extend beyond electrical performance. With its robust design, this type of wire is better equipped to withstand harsh conditions, including extreme temperatures and mechanical stress. A study published in the Journal of Electrical Engineering highlighted that Eaw wrapped wire exhibited a 40% improvement in tensile strength compared to traditional wiring solutions. This durability not only prolongs the lifespan of electrical installations but also minimizes downtime and maintenance costs, ultimately providing a safer operational environment. As industries push for higher efficiency and safety standards, the adoption of Eaw wrapped wire becomes increasingly vital.

Eaw wrapped wire has emerged as a vital component in renewable energy solutions, showcasing innovative applications that enhance efficiency and sustainability. One significant use is in the construction of solar panels, where Eaw wrapped wire acts as conductive pathways that maximize energy transfer from photovoltaic cells. This specialized wire reduces energy loss, ensuring that solar installations operate at optimal performance. Furthermore, its resistance to environmental factors makes it ideal for outdoor applications, prolonging the lifespan of solar systems.

In wind energy systems, Eaw wrapped wire is utilized in the wiring of generators and transformers. The wire's durability and lightweight properties facilitate easier installation and maintenance of wind turbines. Additionally, its ability to handle high temperatures and resist corrosion ensures consistent performance in harsh wind environments. As renewable energy technologies continue to evolve, the integration of Eaw wrapped wire not only supports current infrastructure but also paves the way for future advancements, driving the adoption of greener energy sources worldwide.

Eaw wrapped wire plays a crucial role in enhancing infrastructure durability, providing a reliable solution for various structural applications. Its unique properties, including resistance to environmental factors and mechanical stress, make it an ideal choice for sectors such as construction and telecommunications. By incorporating Eaw wrapped wire, industries can minimize the risk of damage caused by corrosion and wear over time, significantly extending the lifespan of infrastructures.

Tips: When selecting Eaw wrapped wire for your projects, consider the environmental conditions it will face. Opt for wire designed for high corrosion resistance if you're working in a coastal area or a region with high humidity. Additionally, regular maintenance checks can help identify any wear or damage early, ensuring the continued integrity of your structures.

The adaptability of Eaw wrapped wire allows for a variety of applications, from reinforcement in concrete to wiring systems in buildings. As engineers and architects increasingly recognize its benefits, the demand for Eaw wrapped wire in improving infrastructure integrity grows. Choosing the right specifications and implementing best practices in installation can further enhance its effectiveness in safeguarding our built environment.

As industries continue to evolve, the demand for advanced materials such as Eaw wrapped wire is becoming increasingly critical. This innovative wire technology offers enhanced electrical and mechanical properties, making it ideal for various emerging sectors, including renewable energy, electric vehicles, and smart grid applications. The ability to withstand higher temperatures and provide better insulation makes Eaw wrapped wire particularly suited for electric vehicle batteries and charging systems, where efficiency and reliability are paramount.

Moreover, the integration of Eaw wrapped wire into the Internet of Things (IoT) devices is anticipated to revolutionize the way we interact with technology. With the rise of smart homes and connected devices, the need for wires that reduce electromagnetic interference and improve signal integrity is crucial. Eaw wrapped wire not only meets these demands but also enhances the performance of sensors and communication systems in smart technologies, paving the way for more efficient and sustainable solutions. As these trends continue to unfold, Eaw wrapped wire is poised to play a pivotal role in shaping the future of innovation across multiple industries.