Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of electrical engineering and electronics, the selection of materials plays a crucial role in the performance and longevity of projects. Among these materials, Enameled Copper Wire stands out due to its excellent electrical conductivity and thermal properties. According to a recent market report from Technavio, the global enameled wire market is expected to grow by approximately 5% annually, underscoring the increasing demand for high-quality wiring solutions in various applications such as motors, transformers, and inductors.

As industry expert Dr. Emily Chen highlights, "The choice of enameled copper wire directly impacts the efficiency of electrical devices. A well-chosen wire can enhance performance while minimizing energy losses." This underscores the importance of making informed decisions when selecting Enameled Copper Wire for specific projects. With countless options available, understanding the key factors that influence wire quality can lead to optimal project outcomes, ensuring both safety and effectiveness in electrical connections.

This guide aims to provide ten essential tips for selecting the right Enameled Copper Wire, highlighting key considerations from gauge and insulation type to environmental factors and application suitability. By following these recommendations, engineers and DIY enthusiasts alike can enhance their projects while navigating the complexities of wire selection.

Enameled copper wire is a popular choice for a variety of electrical and artistic projects, owing to its unique properties. Understanding its composition is essential: the wire is composed of a copper core coated with a thin layer of enamel insulation. This insulation not only protects the wire from oxidation but also enhances its electrical conductivity. The enamel coating allows for tighter winding in applications like motors, transformers, and inductors, where space is often at a premium.

When selecting enameled copper wire for your project, consider the wire gauge, enamel type, and thermal rating. The gauge affects both the wire's current-carrying capacity and the flexibility, essential for intricate designs. Different enamel types provide varying levels of thermal resistance and durability, which can impact longevity in high-temperature environments. Furthermore, understanding the thermal rating ensures you choose a wire that can withstand the temperature extremes relevant to your project. Knowledge of these factors will empower you to make informed decisions, ultimately leading to successful project outcomes.

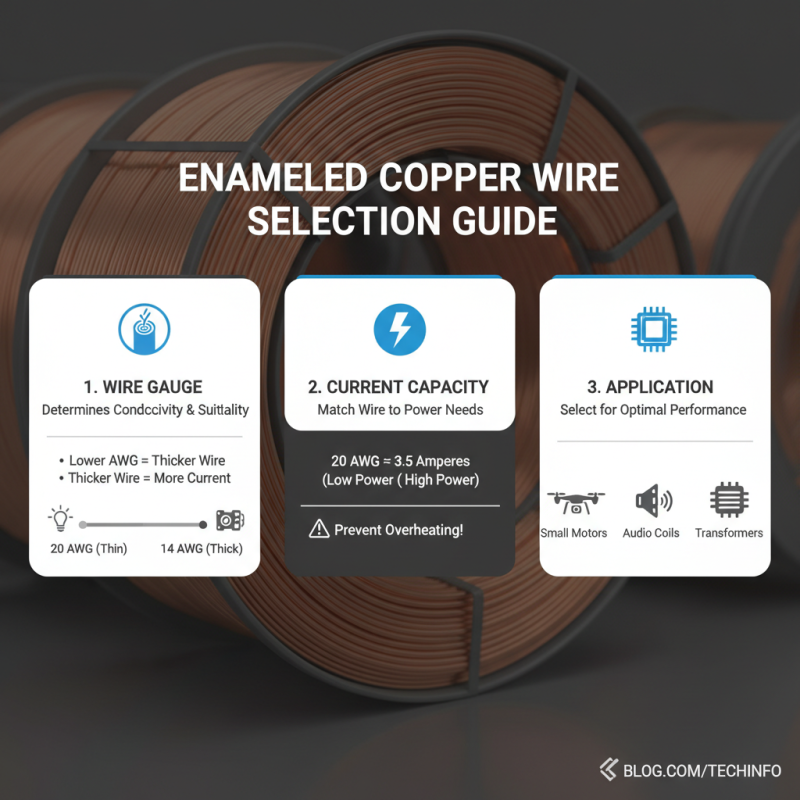

When selecting enameled copper wire for your projects, several key factors should be at the forefront of your decision-making process. First and foremost is the wire gauge, which impacts both the wire's conductivity and its suitability for specific applications. According to the American Wire Gauge (AWG) standard, a lower gauge number indicates a thicker wire, which typically can handle more current. For instance, a 20 AWG wire can safely carry around 3.5 amperes, making it ideal for low-power applications, while options like 14 AWG can support up to 15 amps, suitable for higher load requirements. Understanding your current needs is essential to prevent overheating and ensure optimal performance.

Another critical factor is the enamel insulation type, which directly affects the wire's durability and resistance to environmental factors. Most enameled copper wires utilize polyurethane, polyamide, or polyester insulation, each offering varying levels of heat resistance and chemical durability. Data from the International Electrotechnical Commission (IEC) suggests that wires with high-temperature ratings above 180°C are crucial for applications involving transformers and motors, which often operate under intense conditions. Evaluating the thermal limits of the wire will help ensure it meets the demands of your particular project and aids in mitigating potential failure due to overheating or insulation breakdown over time.

When selecting enameled copper wire for your projects, understanding the different grades available is crucial to ensuring optimum performance. Enameled copper wire is typically categorized into various grades based on its insulation properties, temperature ratings, and intended applications. For instance, according to the International Electrotechnical Commission (IEC), Class 130 (B) enameled wire can withstand temperatures up to 130°C, while Class 180 (H) can handle temperatures up to 180°C, making them suitable for different environments, such as industrial motors versus home appliances.

When making a choice, consider factors like wire gauge and insulation type, as they greatly affect both conductivity and flexibility. A report from the Copper Development Association emphasizes that finer gauge wire minimizes resistive heating, which can significantly enhance efficiency in electrical applications. For projects requiring high precision, using a high-grade enameled copper wire, such as those treated with superior insulation coatings, can improve durability and electrical performance.

Tip: Always verify the temperature rating and insulation type to match your project's requirements to ensure reliability and longevity. Another important point is to assess the thermal stability of the wire, as higher quality enamel coatings resist degradation better, contributing to longer-lasting results.

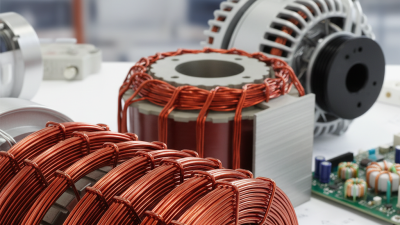

Enameled copper wire is widely used in various applications due to its exceptional electrical conductivity and thermal resistance. One of the most common uses is in the field of electromagnetics, particularly in the manufacturing of transformers and inductors. According to a report by the International Copper Association, the demand for enameled copper wire in the transformer segment alone is projected to reach approximately $2 billion by 2025, driven by the growing need for energy-efficient solutions in power generation and distribution systems.

Additionally, enameled copper wire is essential in the production of electric motors and generators. Its insulation properties allow for high winding density, which is crucial for enhancing motor efficiency. A recent market analysis revealed that the global market for electric motors, which employs substantial amounts of enameled copper wire, is expected to grow by over 6% annually, reaching a value of $160 billion by 2024. This growth underscores the significance of enameled copper wire in accelerating advancements in renewable energy technologies, where efficient motor operation is critical.

Additionally, enameled copper wire is essential in the production of electric motors and generators. Its insulation properties allow for high winding density, which is crucial for enhancing motor efficiency. A recent market analysis revealed that the global market for electric motors, which employs substantial amounts of enameled copper wire, is expected to grow by over 6% annually, reaching a value of $160 billion by 2024. This growth underscores the significance of enameled copper wire in accelerating advancements in renewable energy technologies, where efficient motor operation is critical.

Furthermore, in consumer electronics, enameled copper wire is utilized for winding coils in headphones and other audio devices, contributing to superior sound quality. The global trend towards compact and efficient electronics is further propelling the use of high-quality enameled copper wire. With applications ranging from automotive to aerospace, the versatility of enameled copper wire makes it a critical component in modern technology, supported by significant industry growth forecasts.

Furthermore, in consumer electronics, enameled copper wire is utilized for winding coils in headphones and other audio devices, contributing to superior sound quality. The global trend towards compact and efficient electronics is further propelling the use of high-quality enameled copper wire. With applications ranging from automotive to aerospace, the versatility of enameled copper wire makes it a critical component in modern technology, supported by significant industry growth forecasts.

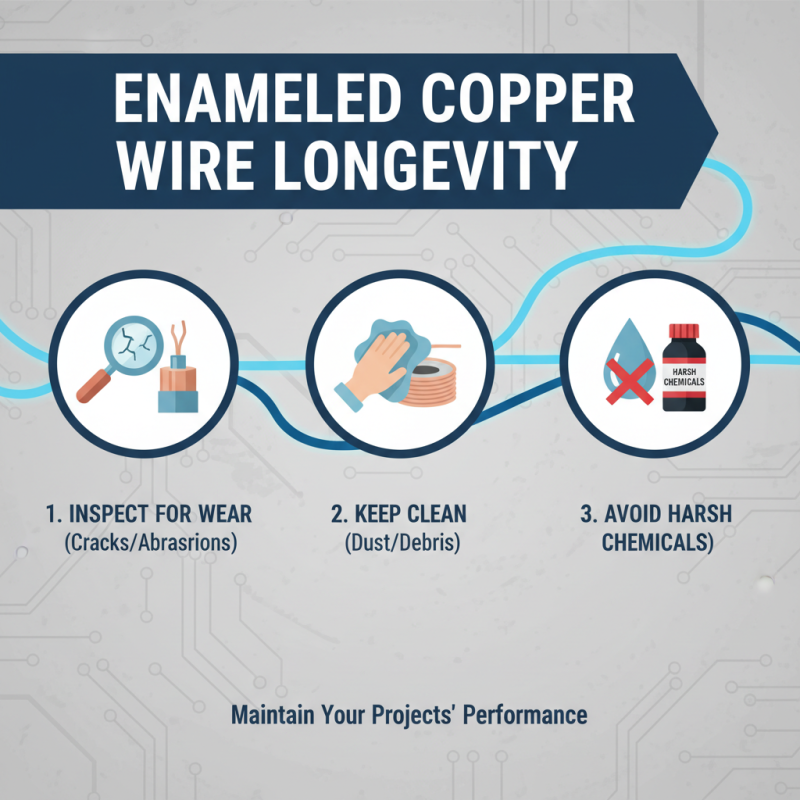

To ensure the longevity of enameled copper wire in your projects, proper maintenance is crucial. One of the primary steps to take is to regularly inspect the wire for any signs of wear or damage. Look for imperfections in the enamel coating, such as cracks or abrasions, which can compromise the wire’s insulation properties. Keeping the wire clean is also essential; dust and debris can lead to corrosion over time. Use a soft cloth to wipe down the surface, avoiding harsh chemicals that may damage the enamel.

Another vital aspect of maintaining enameled copper wire is managing its storage conditions. Store the wire in a dry, cool environment, away from direct sunlight and moisture, which can cause deterioration. If the wire is coiled, avoid tight bends to prevent kinks, which can weaken the structure and lead to breakage. Additionally, when using the wire in your projects, be mindful of the temperatures it is subjected to. Excessive heat can melt the enamel, leading to electrical failures. By following these maintenance tips, you can significantly extend the life of your enameled copper wire, ensuring reliable performance for all your electrical applications.