Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the world of electronics, precision is key. An Enameled Wire Stripper is essential for many projects. Expert Mark Johnson once stated, "Using the right tools can make or break your project." This is especially true for stripping enameled wire.

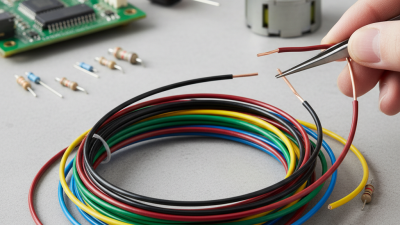

When dealing with delicate wires, a reliable stripper ensures that you remove insulation without damaging the conductor. Many hobbyists overlook this tool. They might think any wire stripper will suffice, but that's not the case. An Enameled Wire Stripper is specifically designed for this task. It makes a significant difference in quality and efficiency.

Imagine working on a delicate circuit and struggling with inadequate tools. You might find yourself frustrated, wasting time. It's crucial to have the right equipment. Investing in an Enameled Wire Stripper can save you from unnecessary setbacks. Not only does it improve your results, but it also enhances your overall experience. Embrace the power of proper tools to elevate your projects to new heights.

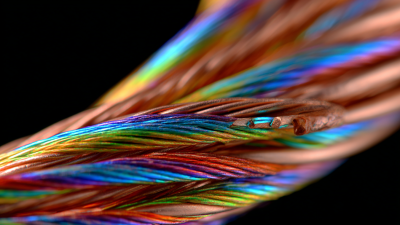

Enameled wire is crucial in various electrical projects. It provides insulation that prevents short circuits. The insulation layer is thin, yet effective. According to industry reports, enameled wire can handle higher temperatures. This durability makes it suitable for motors and transformers.

Using enameled wire increases the efficiency of electrical devices. This type of wire has better resistance to wear and tear. For instance, a study shows that enameled wire can improve coil performance. It helps maintain electrical integrity while decreasing energy losses. However, stripping this insulation manually can be challenging. Improper techniques lead to wire damage, risking project failure.

Investing in an enameled wire stripper simplifies the process. This tool ensures clean cuts without degrading the wire. A study by the Electrical Engineering Society highlights that proper stripping methods can enhance wire performance by 15%. Yet, many hobbyists overlook this equipment. They often prioritize other tools, resulting in poor wiring practices. This neglect can lead to circuit failures or malfunctions. Thus, understanding the importance of enameled wire and proper handling is essential for project success.

Enameled wire stripping tools are essential for many electrical projects. Understanding their mechanism helps in efficient usage. These tools remove insulation from enameled wires without damaging the metal core. This is crucial for ensuring proper electrical conductivity and overall project safety.

According to a report by the International Association of Electrical Inspectors, improper wire stripping can reduce conductivity by up to 30%. This impacts performance significantly. Enameled wire strippers use precise cutting edges that resist wear, enabling clean strips. This reduces the risk of shorts and unexpected failures in projects.

However, not all users understand the tool's functionality. Some may struggle with achieving consistent results. Users should practice to gain proficiency. Mistakes can lead to wasted materials and time. Ensuring correct application of the tool enhances its effectiveness. This experience may be frustrating at first, but practice yields better outcomes.

| Feature | Description | Advantages |

|---|---|---|

| Precision Cutting | Fine blades for cutting enameled wire without damaging the conductor. | Ensures a clean and accurate strip for optimal connectivity. |

| Ergonomic Design | Comfortable grip that reduces hand fatigue during extended use. | Enhances user experience and efficiency in wire stripping tasks. |

| Multiple Gauge Support | Handles various wire gauges for versatile applications. | Ideal for different projects without needing multiple tools. |

| Durable Materials | Made with high-quality materials for longevity. | Reduces the need for frequent replacements, saving money over time. |

| Safety Features | Includes safety mechanisms to prevent accidental injuries. | Provides peace of mind during operation. |

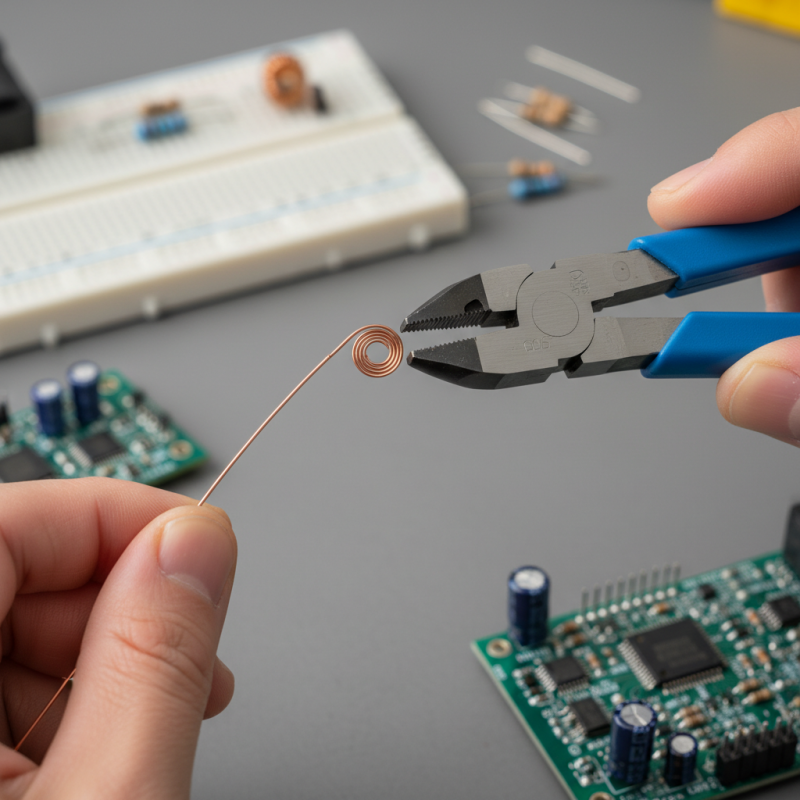

Using an enameled wire stripper is essential for any electrical project. This tool efficiently removes insulation from enameled wires, which can be tricky. A study from the Institute of Electrical and Electronics Engineers (IEEE) shows that using a proper wire stripper can increase productivity by up to 30%. This statistic highlights the significance of this specific tool in ensuring quality work.

Enameled wire strippers allow for precision. They reduce the risk of damaging the wire, which can lead to faults. Traditional methods often lead to frustration. A report by the National Electrical Contractors Association found that approximately 15% of rework stems from improper insulation removal. By using the right tool, you can avoid these costly mistakes.

Tips: Always check the blades for sharpness before use. Dull blades increase the chance of damaging wires. Additionally, practice on scrap wire first. This builds confidence in your technique. Finally, consider the gauge of wire you’re working with. Not all strippers handle every gauge effectively. Making the right choice is crucial for the success of your project.

When working with enameled wires, understanding wire resistance and insulation standards is crucial. The National Electrical Code (NEC) stipulates specific resistance parameters to ensure safety. Enameled wires often exhibit lower resistance, contributing to better electrical efficiency in various applications.

Different industries adopt standards for wire insulation. The International Electrotechnical Commission (IEC) specifies minimum insulation resistance of 1 MΩ for many applications. In real-world projects, failing to meet this criterion can lead to overheating and equipment failure. It's alarming to note that an estimated 25% of electrical failures are linked to inadequate insulation.

Using an enameled wire stripper reduces the risk of damaging the insulation during preparation. Inaccurate stripping can compromise the insulation integrity. This oversight can spark severe electrical incidents. Skilled technicians must pay attention to every detail. Ensuring proper preparation prevents costly errors and enhances project reliability.

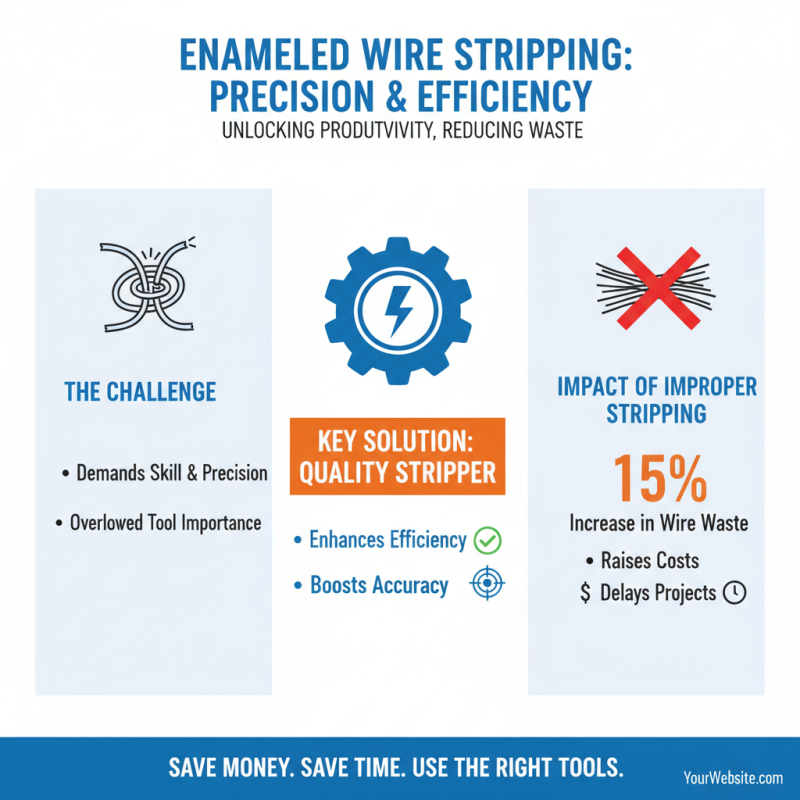

In electrical applications, the stripping of enameled wire demands precision and skill. Many technicians overlook the significance of using the right tools. A high-quality enameled wire stripper can enhance efficiency and accuracy. According to industry studies, improper stripping can lead to a 15% increase in wire waste. This loss not only raises costs but also impacts overall project timelines.

Best practices emphasize preparing the wire before stripping. Clean the area and ensure there are no visible flaws. The average technician spends around 20% of their time managing wire-related issues. Detailed attention to the stripping process cuts errors and improves performance. Additionally, using the correct stripping technique matters. For instance, a firm yet gentle grip can prevent damaging the wire’s conducting core. However, many still rely on outdated methods, causing frustration and setbacks.

Moreover, optimal temperature control is crucial during the stripping process. Excess heat can ruin the enamel insulation and compromise conductivity. Studies show that 30% of electrical failures stem from improper insulation handling. Even small mistakes, like uneven pressure, can lead to significant problems. Reflection on these practices reveals that constant learning and adapting are vital in achieving consistent results.