Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Enameled Copper Wire is a vital component in electrical applications. Its unique properties make it suitable for various uses. This wire is known for its excellent conductivity and high thermal resistance. It is often used in motors, transformers, and other electrical devices.

One of the key benefits of Enameled Copper Wire is its insulation. The enamel coating prevents short circuits and electrical failures. This feature enhances the longevity of electrical devices. Moreover, the wire's flexibility allows for easy handling and installation.

However, there are challenges too. Not all enameled wires meet the same quality standards. Some may not withstand high temperatures. Users must choose wisely to avoid future issues. Despite these concerns, the advantages of Enameled Copper Wire often outweigh the drawbacks. Its efficiency and reliability make it a popular choice in the electrical industry.

Enameled copper wire is a crucial component in numerous electrical applications. It is composed of copper wire coated with a thin layer of insulating enamel. This insulation is vital as it prevents short circuits while maintaining electrical efficiency. The copper core ensures excellent conductivity, making it a popular choice for motors, transformers, and other electronic devices.

Tips: When selecting enameled copper wire, consider the thickness of the enamel. Thicker enamel provides better insulation but can limit flexibility. Think about your project's specific needs.

Another essential aspect is the wire's temperature rating. Different applications require varying heat resistance levels. Choosing the wrong rating may lead to failures or outages. Pay attention to the environment where the wire will be used.

Tips: Perform a visual inspection before use. Look for any signs of wear or damage. A small flaw can compromise the wire's performance. Ensure your wire meets the necessary standards for safety and functionality.

Enameled copper wire is a popular choice in electrical applications. Its unique coating provides excellent insulation, which enhances the efficiency of various devices. The enamel coating protects the copper from corrosion and prevents shorts. This feature is crucial in environments with high humidity or temperature fluctuations.

One major advantage is its flexibility. Enameled wire can easily be shaped for complex designs. This allows engineers to create compact devices. However, this flexibility can also lead to issues. Sometimes, wires may get tangled or damaged during installation. Proper handling is essential to avoid this.

The wire also exhibits impressive thermal conductivity. This property ensures minimal energy loss during operation. Over time, though, heat can degrade insulation if not properly managed. Regular inspections are vital to maintain safety. While enameled copper wire is efficient, it requires cautious use. The balance between its benefits and potential pitfalls is important for electrical applications.

Enameled copper wire is gaining popularity in electrical applications. Its thermal and electrical properties offer advantages over traditional wiring. A study by the International Journal of Electrical Engineering reported that enameled copper wire has lower resistance, allowing for improved efficiency in circuits. This can lead to a reduction in energy consumption, something crucial for many industries.

Compared to traditional wiring, enameled copper wire boasts better insulation and durability. The enamel coating provides protection against moisture and chemicals. According to research by the National Electrical Manufacturers Association, this leads to a 30% longer lifespan compared to uncoated wires. However, the initial cost can be higher. Many still hesitate to adopt the more advanced options.

Despite the benefits, challenges remain. Installation can be more complex. Technicians may require additional training to handle enameled wires correctly. The fine enamel coating can be problematic if damaged during installation. Industry reports suggest that as awareness grows, these concerns are slowly being addressed. The potential for innovation in this field is significant, but some roadblocks need to be overcome.

| Feature | Enameled Copper Wire | Traditional Wiring |

|---|---|---|

| Conductivity | High conductivity due to pure copper | Good conductivity but may have alloy components |

| Insulation | Enhanced insulation with enamel coating | Standard insulation materials |

| Durability | Highly durable and resistant to abrasion | Less durable, susceptible to wear and tear |

| Heat Resistance | High heat resistance due to enamel | Variable heat resistance depending on materials used |

| Weight | Lightweight, reducing installation costs | Heavier, potentially increasing transport and installation costs |

| Applications | Widely used in motors and transformers | Used in basic electrical wiring |

Enameled copper wire is crucial in many sectors. Its applications span across electrical equipment, automotive industries, and home appliances. The wire's insulation helps prevent short circuits and offers durability. In motors and generators, this wire improves efficiency and performance.

In the electrical industry, enameled copper wire is preferred for winding. It minimizes energy loss, which is essential for high-performance devices. Telecommunication systems also rely on this wire for signal transmission. The insulation protects against interference, ensuring clearer communication. However, the production process can involve challenges, such as inconsistent thickness in coating.

In the automotive industry, enameled copper wire powers electric vehicles. It is lightweight and helps reduce overall vehicle weight. This wire is also used in various sensors and electronic components. Yet, there is always room for improvement in thermal management. Effective heat dissipation remains a concern as vehicles become more advanced. Overall, enameled copper wire continues to be vital but must adapt to evolving technologies.

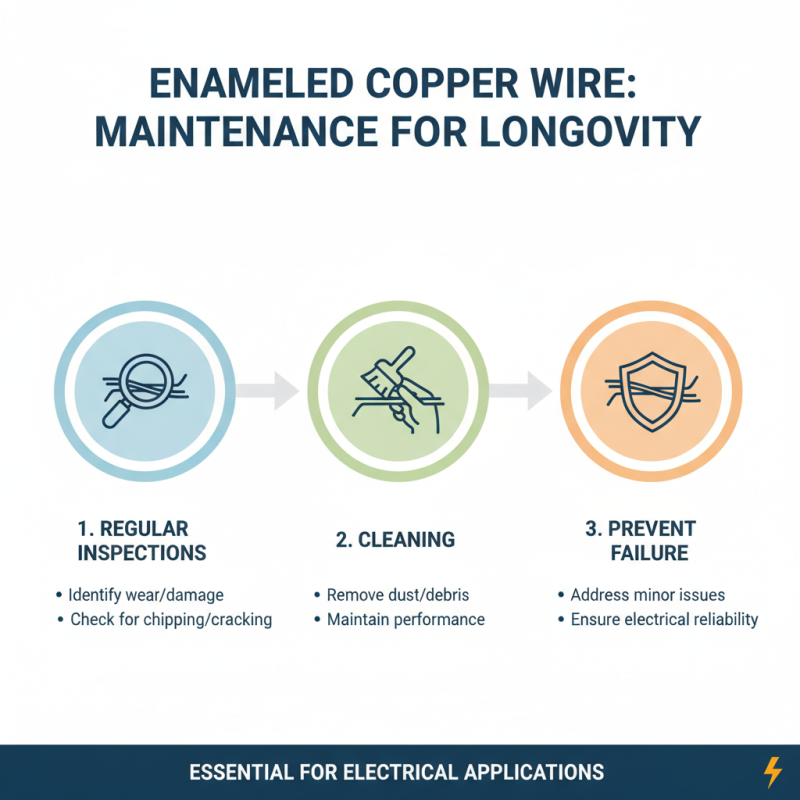

Enameled copper wire is widely used in electrical applications. However, proper maintenance is essential to ensure its longevity. Regular inspections can help identify wear or damages. Look for signs of chipping or cracking in the enamel. Even minor issues can lead to significant failures over time. Cleaning the wire is also important. Dust and debris can accumulate, impacting performance.

Safety considerations should not be overlooked. Always handle the wire with care to avoid cuts or scratches. If the enamel is compromised, the wire may short circuit. This poses fire risks or equipment damage. Using protective gear during installation is a smart choice. Ensure that connections are tight but not overly stressed. Over-tightening can cause insulation damage.

It’s essential to store enameled copper wire properly. Excessive humidity can degrade the insulation. Wrap the wire securely and keep it in a dry location. Environmental factors play a huge role in the wire's durability. Take note of temperature fluctuations, as extreme heat or cold might cause the enamel to crack. Keeping all these factors in mind will ensure your electrical systems run smoothly.