Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

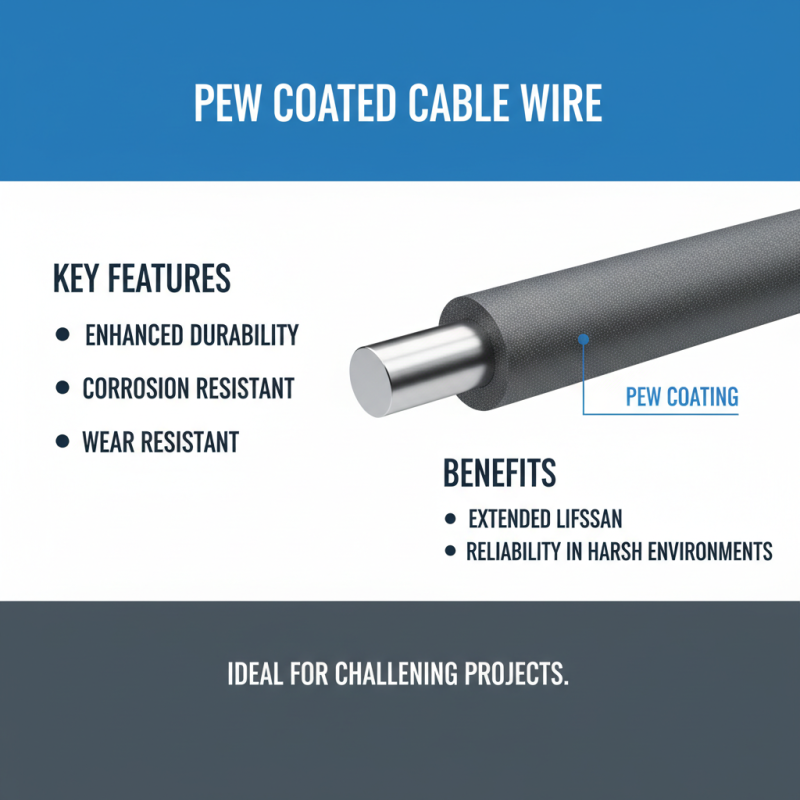

Choosing the right materials for your projects can make all the difference. One important option is Pew Coated Cable Wire. This wire offers unique benefits that enhance durability and performance. It is a popular choice in various applications.

Pew Coated Cable Wire resists corrosion effectively. This protection is crucial in environments with moisture. The long-lasting nature of the coating can prevent costly repairs or replacements. While other wires may fail, this option stands strong against the elements.

However, it's essential to reflect on your specific needs. Pew Coated Cable Wire may not always be the cheapest option. Sometimes, you might question if the investment is worth it. Yet, considering its longevity can lead to fewer headaches down the road. Choosing this wire may require careful thought, but its advantages often outweigh the initial costs.

Pew coated cable wire stands out for various reasons. Its unique coating offers enhanced durability. This makes it resistant to corrosion and wear. In challenging environments, where moisture and chemicals are present, pew coated wire performs admirably. It protects the inner metal core, ensuring longevity. Projects requiring reliability often benefit from this material.

Additionally, the flexibility of pew coated cable wire is noteworthy. It is easy to handle and install. Whether for electrical work or structural applications, this wire adapts well. However, some may overlook its cost-effectiveness. Investing in pew coated options can save on maintenance. A thoughtful assessment of project needs is crucial.

Some might think all wires are the same. But the properties of pew coated cable wire challenge this notion. Understanding the benefits can lead to more informed decisions. This choice might seem minor but has significant implications. In the long run, selecting the right materials can enhance project outcomes.

Choosing pew coated cable wire can significantly enhance the quality of your projects. This type of wire offers excellent corrosion resistance. It is ideal for outdoor applications or environments exposed to moisture. The coating protects the inner wire effectively, extending its lifespan. Users often notice fewer maintenance issues over time.

In construction and DIY projects, pew coated wire shines. It provides reliable electrical performance and stability. You can use it for various purposes, from wiring to creating secure connections. It's versatile enough for both residential and commercial work. However, some may find it slightly more expensive than traditional wiring options. The difference in long-term durability often justifies the cost.

Some drawbacks exist, though. Not all pew coated wires are created equal, which can lead to confusion. Also, installation may require specific tools due to its unique properties. There are tips to consider when choosing the right type for your needs. Take your time to evaluate options. Each project is unique, and the wire you choose matters.

| Project Type | Advantages of Pew Coated Wire | Typical Applications |

|---|---|---|

| Construction | Corrosion resistance, enhanced durability | Reinforcements, electrical wiring |

| Electrical Projects | Improved insulation, reduced interference | Harnesses, switches, connectors |

| Telecommunications | High tensile strength, flexibility | Cables, antennas |

| Marine Applications | Resistant to saltwater corrosion | Boat wiring, marine infrastructure |

| Industrial Use | High durability against abrasions | Machinery wiring, heavy-duty applications |

When comparing Pew Coated Cable Wire with other wire types, several factors come into play. Pew coating offers superior resistance to corrosion. This is vital for projects exposed to moisture and harsh environments. Traditional wires, often made of bare metal, may rust easily. This weakens their strength over time. Pew-coated wires maintain integrity longer, ensuring reliability.

Another aspect to consider is flexibility. Pew coated wires are generally easier to handle. They can be bent and shaped without breaking. Other wires may become brittle, especially in cold conditions. This can limit their application in specific projects. However, pew coating isn’t perfect. It can wear off in high-friction areas. Thus, understanding the environment is crucial.

Cost is another consideration. Pew coated wires may come with a higher price tag compared to standard options. This might deter budget-conscious projects. Analyzing long-term benefits versus short-term costs becomes essential. Sometimes, investing more upfront pays off down the line. Each project has unique needs that must be evaluated carefully.

When selecting pew coated cable wire, one must consider several factors. The wire's durability is crucial. It should withstand harsh environments. Look for resistance to corrosion and wear. This is especially important for outdoor projects. A reliable coating can make a significant difference.

Another key aspect is flexibility. The wire needs to adapt to various applications. If it's too rigid, it may not fit your design. Ensure it can handle bends and twists without breaking. Testing the wire's limits might be necessary. It’s okay if you don’t get it right the first time.

Moreover, gauge size matters. Thicker wires may handle more load. However, they can be heavier and harder to work with. Light wires are easier to install, yet may not support heavy equipment. Consider your project's specific needs. It can be tricky, and mistakes may happen. Experimenting can lead to the best choice for your application.

Pew coated cable wire is gaining popularity in various applications. Its unique properties make it ideal for demanding environments. Many industries benefit from its durability, corrosion resistance, and versatility. Manufacturing, construction, and telecommunications are just a few examples.

In manufacturing, pew coated wire is often used in machinery and equipment. It withstands high temperatures and is resistant to chemicals. This reliability means less downtime for repairs. In construction, this wire serves as effective reinforcement. It enhances structural integrity, especially in bridges and buildings.

**Tips:** Choose the right gauge for your project. Thicker wire provides more strength but can be harder to work with. Consider your project's specific needs before making a selection. In telecommunications, pew coated wire offers reliable connectivity. It protects against environmental factors that can disrupt signals.

Using pew coated cable wire does have its challenges. It may cost more than standard options. However, its longevity can offset these expenses over time. It's essential to weigh both short-term costs and long-term benefits. Understanding the balance can lead to better project outcomes.

This bar chart illustrates the various industries that benefit from using Pew Coated Cable Wire. Each sector shows a percentage indicating the advantages afforded by this type of cable, which is crucial for enhancing durability and performance in numerous applications.