Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

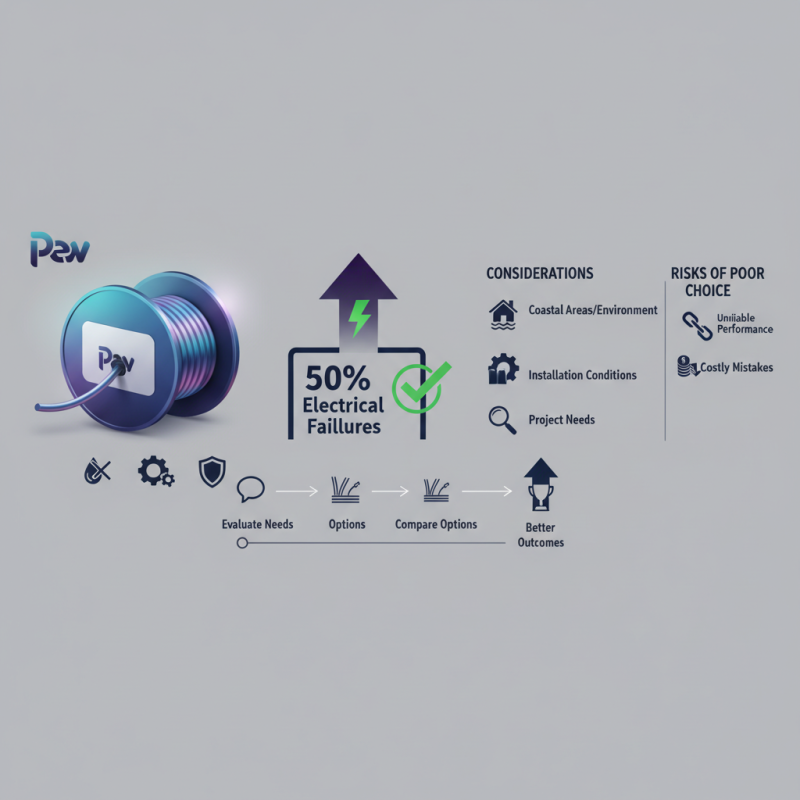

Choosing the right Pew Coated Cable Wire is crucial for project success. In recent years, industry reports show that over 50% of electrical failures stem from poor wire selection. The right cable ensures safety and efficiency. Pew Coated Cable Wire offers unique benefits that can enhance durability and resistance to harsh environments.

When selecting this wire, consider your project's specific needs. For instance, Pew Coated Cable Wire is resistant to corrosion, which can be a game-changer in coastal areas. However, the market is flooded with options. Not all products are made equally. Some manufacturers sacrifice quality for price, leading to unreliable performance.

Moreover, installation conditions vary significantly. It’s vital to choose a wire that can withstand environmental stressors while remaining easy to work with. Reflecting on project requirements is essential. Misjudgment can lead to costly mistakes. Taking time to evaluate your needs and options will ultimately yield better outcomes.

Pew coated cable wire is popular in various projects. It offers excellent protection against corrosion and enhances electrical conductivity. Understanding its basic features can help you make informed choices.

The pew coating creates a thin, protective layer over the wire. This layer helps in preventing wear and tear. It is essential for outdoor applications, especially in harsh environments. The coating also makes the wire more d durable. You may find that some cables may not perform well under extreme conditions.

When choosing a pew coated cable wire, consider the thickness of the coating. A thicker layer may provide better insulation. However, it could also affect flexibility. Balancing durability and flexibility is crucial. Sometimes, it’s tricky to find the right fit for your specific needs. Avoid rushing this decision; take time to research and compare options.

Choosing the right pew coated cable wire requires understanding your project's specific requirements. Factors like environment, load capacity, and electrical standards are crucial. A project involving high humidity may require a different wire coating than one in a dry area. According to a recent industry report, around 30% of failures in electrical installations stem from inadequate cable selection.

It's important to evaluate the mechanical properties as well. For overhead applications, you might need a wire that can withstand tension and environmental stress. Research indicates that tensile strength variations can impact durability by over 20%. Sometimes, projects are rushed, leading to poor material choices. This oversight can result in costly repairs down the line.

Consider the insulation type too. It affects both safety and performance. A study showed that 40% of circuit malfunctions are linked to insulation degradation. Not paying attention to your project specifics could lead to significant issues. Simple factors can have complex consequences. Reflecting on these choices is key.

When selecting pew coated cable wire for your projects, it’s essential to evaluate the different types available. Pew coating offers durability and resistance to corrosion. These features make it popular in various applications. Some cables come with a thicker coating, providing extra protection. Consider how much wear and tear your project may face.

The wire gauge matters too. Thinner wires are more flexible but less durable. Thicker wires offer greater strength but can be harder to work with. Assess your project's specific needs. Will it require frequent bending? Or can you afford to use a stiffer wire?

Each type of pew coated wire has its trade-offs. Some users find that over time, even a durable coating can wear off. This leads to vulnerabilities. Reflecting on previous projects might help in making better choices. What worked well? What didn't? Always keep your project demands and potential compromises in mind.

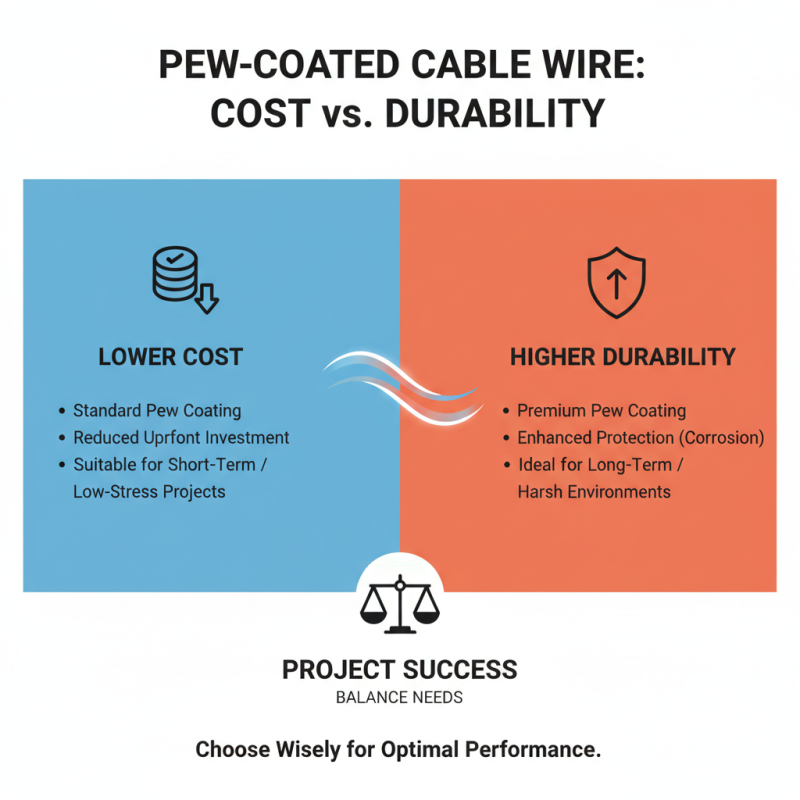

When it comes to selecting pew coated cable wire, cost and durability are key factors. Different projects have varying demands. High-quality pew coatings can offer enhanced protection against corrosion and wear. However, they also come at a higher price. Balancing these two variables is crucial for project success.

In many cases, cheaper cable wires may seem tempting. They can provide immediate savings. Yet, this often comes at the expense of longevity and performance. A lower upfront cost might lead to more frequent replacements. In contrast, investing in more durable options can save money over time. Consider the environment where the cables will be installed. Locations with high moisture or chemical exposure will require tougher materials.

It's also important to reflect on the performance under load. Cables that appear strong may not withstand sustained stress. Look for warranties or certifications. These can offer insights into the wire's reliability. Choosing the right wire is not just about initial costs. It involves considering how long it will last and how much it will ultimately cost.

Choosing a reliable supplier for pew coated cable wire can be challenging. Quality should be your primary concern. Start by researching potential suppliers. Check their experience and reputation in the industry. Look for online reviews or ratings. A supplier with positive feedback often indicates quality products.

Also, consider the materials used. High-quality pew coating enhances durability and performance. Ask for specifications. Don't hesitate to request samples before making a large order. This step often reveals much more than a catalog. Evaluate the sample's finish and texture. Don't ignore minor imperfections. They could impact your project's integrity.

Lastly, establish communication with suppliers. A responsive team signals reliability. Discuss your project requirements and ask questions. Listen to their suggestions. This dialogue can help you gauge their expertise. Trust your instincts during this process. The right supplier can significantly influence your project's success.