Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

When embarking on electrical projects, one of the crucial components to consider is the type of wire used, particularly Enameled Copper Wire. Known for its excellent conductivity and insulation properties, this type of wire is favored by electricians and hobbyists alike. However, with a variety of options available on the market, selecting the right Enameled Copper Wire for your specific needs can be a daunting task. Understanding the characteristics, applications, and advantages of different options can significantly impact the performance and longevity of your electrical systems.

Enameled Copper Wire is crafted by applying an insulating enamel coating to copper wire, which not only enhances its electrical properties but also protects it from environmental factors. In this guide, we will delve into the key aspects that should influence your decision when choosing Enameled Copper Wire. From determining the appropriate gauge for your projects to considering the insulation type and thermal rating, making informed choices will ensure safety and efficiency in your electrical endeavors. Whether you're working on small DIY tasks or larger industrial applications, proper selection of Enameled Copper Wire will play a vital role in the success of your projects.

When it comes to selecting the right enameled copper wire for your electrical projects, understanding the different types available is crucial. There are several key types of enameled copper wire, each with unique properties and applications. For instance, the magnet wire is commonly used in motors, transformers, and inductors due to its excellent insulation and heat resistance. Another type, heavy-duty enameled copper wire, is designed for high-power applications, providing additional durability under extreme conditions. Light-duty versions, on the other hand, are often utilized for less demanding tasks like winding coils and creating small electronic components.

Tips: When choosing the right wire for your project, consider the operating temperature and the environment in which the wire will be used. For high-temperature applications, opt for a wire with a higher thermal rating to ensure longevity and performance. Additionally, always check the wire gauge to make sure it can handle the current load of your project.

Another important factor is the type of insulation used on the enameled copper wire. Polyurethane, polyester, and polyamide are common coatings that offer varying levels of thermal and chemical resistance, making them suitable for a range of applications from automotive to home appliances. Matching the insulation type to your specific electrical requirements will enhance the safety and efficiency of your project.

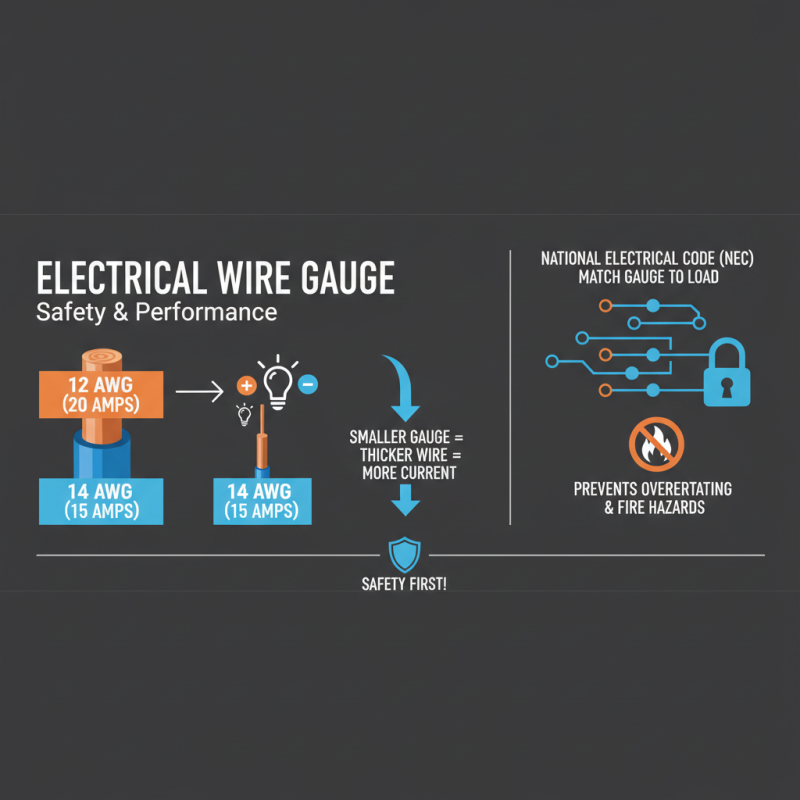

When selecting enameled copper wire for electrical projects, several critical factors must be taken into consideration to ensure optimal performance and longevity. One of the foremost aspects is the wire gauge, which directly influences the current-carrying capacity. According to the National Electrical Code (NEC), using the appropriate gauge helps prevent overheating and ensures safety in electrical systems.

For instance, a 14-gauge wire can handle up to 15 amps, making it suitable for many household applications. Selecting the right gauge based on the intended load is crucial to achieving efficient operation.

For instance, a 14-gauge wire can handle up to 15 amps, making it suitable for many household applications. Selecting the right gauge based on the intended load is crucial to achieving efficient operation.

Another important factor is the type of enamel used for insulation. Enameled copper wires are often coated with different types of insulation materials, such as polyester or polyurethane. Each type has its unique thermal and chemical resistance properties, which can affect the wire's performance in various environments.

A report from the Institute of Electrical and Electronics Engineers (IEEE) highlights that wires insulated with high-performance coatings can withstand higher temperatures and are more resistant to abrasions, thereby extending the life of the wire. Understanding these insulation properties can assist engineers and DIY enthusiasts alike in choosing wires that meet the demands of their specific projects while adhering to safety standards.

A report from the Institute of Electrical and Electronics Engineers (IEEE) highlights that wires insulated with high-performance coatings can withstand higher temperatures and are more resistant to abrasions, thereby extending the life of the wire. Understanding these insulation properties can assist engineers and DIY enthusiasts alike in choosing wires that meet the demands of their specific projects while adhering to safety standards.

When embarking on electrical projects, one critical aspect to consider is wire gauge, which significantly influences performance and safety. Wire gauge refers to the diameter of the wire and is typically measured using the American Wire Gauge (AWG) system. A smaller gauge number indicates a thicker wire, which can carry more current with less resistance. For instance, according to the National Electrical Code (NEC), using a wire gauge suitable for the expected load is essential; a 12 AWG wire can safely conduct up to about 20 amps, while a 14 AWG wire is limited to approximately 15 amps, making the choice of gauge crucial in preventing overheating and potential fire hazards.

Tips: Always check the load requirements of your project and select a wire gauge that not only meets but exceeds these requirements to ensure safety and efficiency. Additionally, consider the length of the wire run; longer distances may require a thicker wire to mitigate voltage drop.

Understanding the importance of wire gauge extends beyond just current-carrying capacity. It also affects the flexibility and insulation properties of the wire. For enameled copper wire, a thicker gauge may mean better conductivity but can reduce flexibility, making it harder to work with in tight spaces. According to a report by the Institute of Electrical and Electronics Engineers (IEEE), selecting the optimal wire gauge contributes significantly to overall project performance and lifespan. Always refer to established guidelines and performance data when making your selection to ensure you achieve the best results for your electrical endeavors.

Tips: For projects with space constraints or varying current levels, consider using multi-stranded wire, which provides both flexibility and enhanced performance over single-strand alternatives.

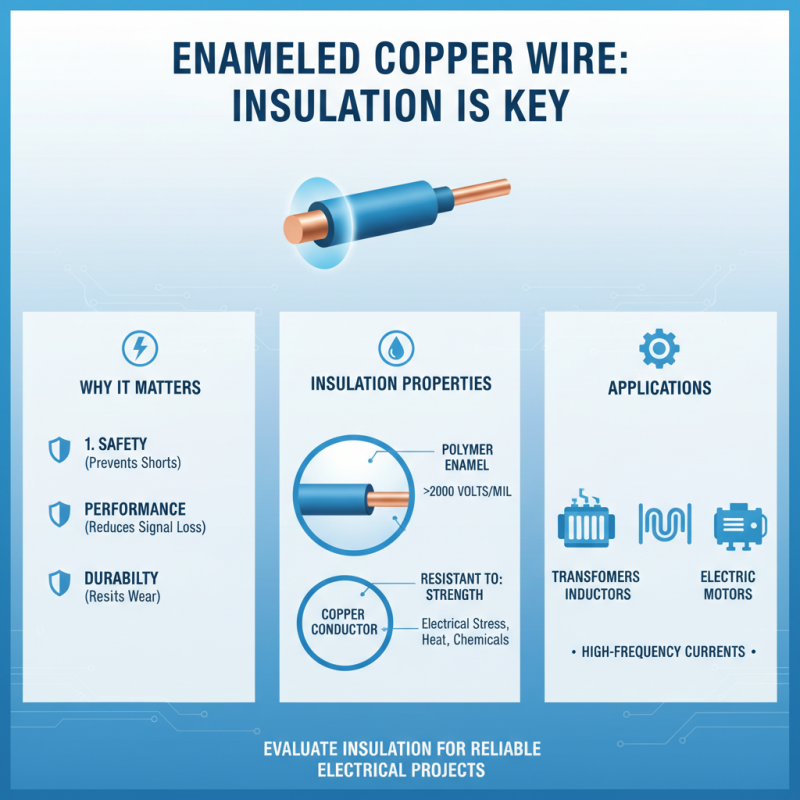

When it comes to selecting enameled copper wire for electrical projects, evaluating the insulation properties is crucial to ensure safety and performance. The insulation material determines the wire's ability to withstand electrical stress, environmental factors, and mechanical wear. For instance, enamel coatings, typically made from polymer materials, provide high dielectric strength, often exceeding 2000 volts per mil of thickness. This characteristic is essential for applications involving high-frequency currents, such as in transformers and inductors, where proper insulation helps prevent signal losses and protects against electrical short-circuits.

Additionally, different insulation types offer varying resistance to heat and chemical exposure. According to a report by the International Electrotechnical Commission (IEC), polyamide-based enamel, which can withstand temperatures up to 220°C, is often preferred for electric motors and generators. In contrast, epoxy-based enamels, while offering excellent mechanical strength, generally have lower thermal resistance, making them suitable for less demanding applications. For optimal performance, it is vital to match the wire's insulation properties with the specific parameters of the electrical project, including operating temperature, environmental conditions, and voltage levels, ensuring reliability and longevity in usage.

When working with enameled copper wire, maintenance and safety are essential to ensure longevity and optimal performance in your electrical projects. To start, it is crucial to inspect the wire regularly for any signs of wear, fraying, or damage. Any observable defects can compromise the performance of your electrical circuit, so replacing damaged sections or completely swapping out the wire is advisable.

Additionally, maintaining proper storage conditions can help prevent damage; keep the wire in a cool, dry place, away from direct sunlight and moisture, to avoid deterioration of the enamel insulation.

Safety precautions should also be a top priority. Always use appropriate protective gear, such as gloves and safety goggles, while handling the wire to avoid injury from sharp edges or flying debris when cutting. Furthermore, when making connections, ensure that the wire is stripped correctly to maintain the integrity of the enamel insulation. Incorrect stripping can lead to short circuits or unintended electrical discharges, which can pose serious hazards. By following these maintenance and safety tips, you can ensure that your enameled copper wire remains reliable and effective for all your electrical applications.