Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

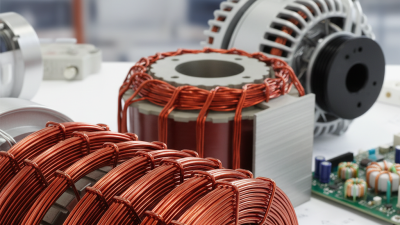

When embarking on a project that requires reliable and durable electrical wiring, selecting the right materials is crucial. Among the various options available in the market, Eaw Coated Cable stands out due to its unique properties and diverse applications. The choice of the appropriate cable directly influences the efficiency, safety, and longevity of your project. This guide aims to help you navigate the decision-making process by outlining essential considerations when selecting Eaw Coated Cable for your specific needs.

Understanding the characteristics of Eaw Coated Cable is vital for making an informed choice. These cables are designed to offer excellent insulation, resistance to various environmental factors, and enhanced durability, which are necessary in many industrial and commercial applications. As you explore the different types of Eaw Coated Cable available, it's important to assess factors such as the cable's electrical specifications, environmental suitability, and installation requirements. By making thoughtful comparisons and evaluations, you can ensure that the cable you choose will meet the demands of your project while maintaining the highest safety standards.

EAW coated cables are becoming increasingly popular in various industries due to their unique properties and advantages. These cables are commonly defined as flexible conductors with a specialized insulation layer that protects them from environmental hazards. One of the key benefits of EAW coated cables is their exceptional resistance to moisture, chemicals, and abrasion, making them ideal for use in harsh conditions. According to industry data, approximately 30% of cable failures in industrial applications are due to environmental factors; thus, utilizing EAW coated cables can significantly reduce downtime and maintenance costs.

When selecting EAW coated cables for your project, consider factors such as temperature range, voltage rating, and specific application requirements. The insulation properties can vary, with certain coatings specifically designed for high-temperature environments or areas exposed to corrosive substances. Reports indicate that projects using the right EAW coated cables can experience a reduction in failure rates by up to 50%, ultimately improving overall operational efficiency.

Tips: Ensure to consult with a technical expert to verify the specifications that best suit your project's conditions. Additionally, always request samples for testing to ascertain the compatibility and performance of the cables in your specific environment. Understanding these attributes will not only enhance the lifespan of your cables but also contribute to the success of your project's performance.

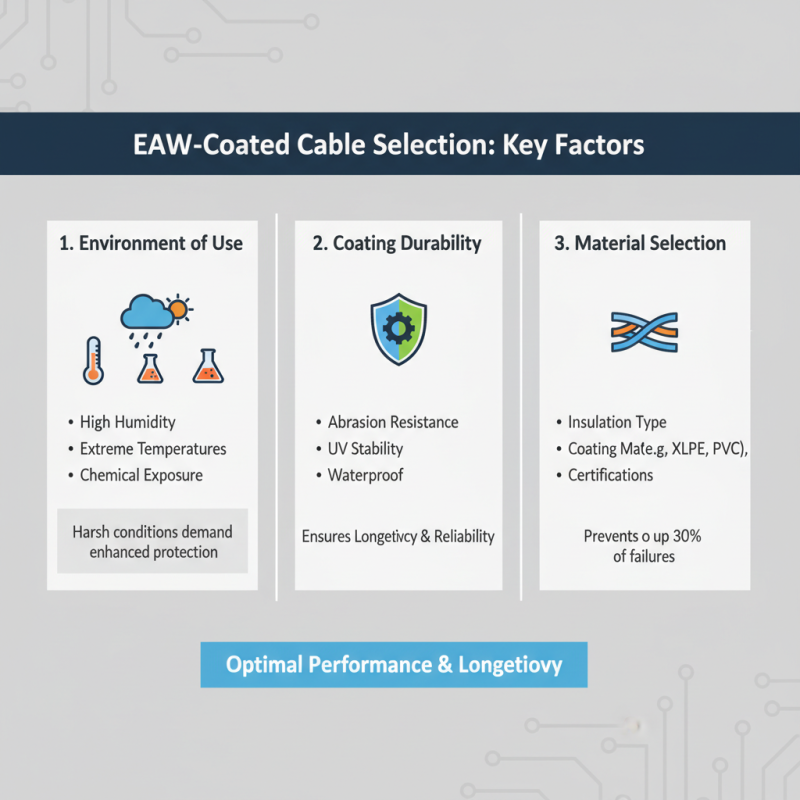

When selecting EAW coated cable for your projects, several key factors must be taken into consideration to ensure optimal performance and longevity. One of the foremost elements is the cable’s environment of use; cables subjected to harsh conditions such as high humidity, extreme temperatures, or chemical exposure require coatings that offer enhanced protection and durability. According to industry reports, up to 30% of cable failures can be attributed to inadequate insulation and environmental stressors, highlighting the necessity of proper material selection.

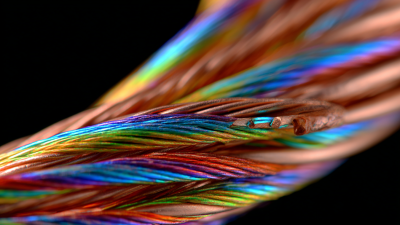

Another critical factor is the specific electrical and mechanical properties required for your application. Data from the International Electrotechnical Commission suggests that the right coating can significantly reduce the risk of abrasion and wear in high-friction environments. When analyzing tensile strength and flexibility, choosing a coated cable with a suitable rating ensures that it can withstand operational demands without compromising safety or efficiency. Additionally, understanding the installation environment will guide decisions on cable thickness and flexibility, which are key to providing reliable connections while limiting installation difficulties.

When selecting the best Eaw coated cable for your project, understanding its performance metrics is crucial. Longevity is a primary factor to consider; a well-constructed cable should endure rigorous conditions over an extended period. Look for cables that can withstand environmental factors like heat, moisture, and mechanical stress without significant degradation. Materials used in the coating and core can significantly influence a cable's lifespan, so ensure they meet industry standards for durability.

Resistance is another essential metric, particularly for projects that involve exposure to chemicals or extreme temperatures. High resistance to abrasion, UV light, and chemical substances can mean the difference between a cable that functions effectively and one that fails prematurely. Flexibility is equally important, especially for applications that require frequent movement or bending. Cables that maintain flexibility without compromising on other performance aspects can simplify installation and help avoid physical damage during operation. Thus, balancing these three elements—longevity, resistance, and flexibility—will lead you to the optimal Eaw coated cable for your needs.

When selecting EAW coated cables for your project, understanding the significance of industry certifications is crucial. Certifications serve as benchmarks that ensure the cables meet safety and performance standards set by authoritative bodies. Common certifications include IEC, UL, and RoHS, each representing different aspects of cable quality, such as electrical safety, environmental impact, and materials compliance. Familiarizing yourself with these certifications can help in making informed decisions regarding the suitability of the cables for your specific application.

Moreover, different projects may have varying requirements, making it essential to choose EAW coated cables that not only meet industry standards but also align with your project's unique needs. For instance, if your project demands high resistance to environmental factors, opting for cables with the relevant environmental certification will provide assurance of durability and reliability. By comparing the certifications and their implications, you can effectively assess the best EAW coated cable options available, ensuring that your project functions optimally while adhering to all necessary regulations.

| Cable Type | Core Matterial | Coating Material | Certification Standards | Temperature Rating | Typical Applications |

|---|---|---|---|---|---|

| EAW Type A | Copper | PVC | UL 83, CSA C22.2 | -20°C to 90°C | Internal Wiring, Control Circuits |

| EAW Type B | Aluminum | Polyethylene | IEEE 383, IEC 60332 | -40°C to 105°C | Outdoor Power Transmission |

| EAW Type C | Copper | LSZH | RoHS, REACH | -10°C to 80°C | Data Centers, Networking |

| EAW Type D | Copper | Rubber | MIL-W-76, ASTM B-3 | -50°C to 125°C | Military, Aerospace |

When selecting the best EAW coated cable for your project, understanding the balance between cost and performance is crucial. Primarily, your budget will dictate the specifications you can afford. Higher quality cables may come with a steeper price tag, but they often provide better durability, flexibility, and overall performance. This can lead to lower long-term costs due to reduced maintenance and longer lifespans.

To effectively budget for your EAW coated cable needs, consider these tips. First, assess the specific requirements of your project—what type of environment will the cable be used in? Ensure that the cable’s properties, such as insulation and temperature tolerance, are aligned with your project needs. Secondly, compare various options available in the market, not just in terms of price, but also in warranty and customer support. Selecting the right option can save you money and headaches down the line.

Keep in mind that while it might be tempting to go for the lowest price, this can lead to compromises in performance. Sometimes investing in a slightly more expensive cable can be more cost-effective when considering its durability and functionality in the long run. Prioritize quality alongside your budget to ensure that your EAW coated cable fulfills its intended purpose efficiently.