Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of electrical projects, the choice of materials can significantly impact performance and efficiency. One standout option is Copper Wire With Enameled Coating, which is praised for its remarkable properties and versatility. Renowned electrical engineer Dr. Emily Carter emphasizes the advantages of this material, stating, "Copper Wire With Enameled Coating not only enhances conductivity but also provides superior insulation, making it ideal for a wide range of applications.”

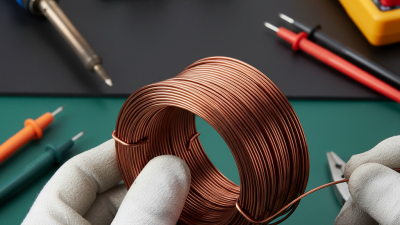

The enameled coating on copper wire serves to protect it from oxidation and environmental factors, thus prolonging its lifespan and reliability. This feature is critical for various electrical applications, where exposure to heat and chemicals can lead to premature failure of standard wiring. As industries increasingly seek solutions that combine durability and efficiency, Copper Wire With Enameled Coating has emerged as a preferred choice for engineers and technicians alike.

In conclusion, when embarking on electrical projects, selecting the right wire is paramount. The unique characteristics of Copper Wire With Enameled Coating offer not only enhanced performance but also ensure safety and longevity in electrical systems. Given its numerous benefits, it stands as a go-to material amongst professionals dedicated to quality and innovation in the field.

When it comes to electrical projects, selecting the right type of wire is crucial for ensuring efficiency and durability. Copper wire with an enameled coating offers numerous benefits that make it a preferred choice for many professionals and DIY enthusiasts. One of the primary advantages of this coating is its excellent insulation properties. The enamel coating acts as a barrier between the wire and surrounding elements, protecting against moisture and corrosion, which can degrade performance over time. This durability is especially beneficial in environments that are prone to temperature fluctuations or exposure to chemicals.

In addition to insulation, enameled coatings significantly enhance the wire's conductivity. The smooth surface of the enamel minimizes resistance, allowing for optimal electrical flow. This efficiency can lead to reduced energy loss and improved performance in applications such as motors, transformers, and other electrical components. Furthermore, the lightweight nature of enameled copper wire allows for easier handling and installation, making it an ideal choice for complex electrical systems.

**Tips for Using Enameled Copper Wire:**

- Always test the wire for conductivity before installation to ensure it meets your project requirements.

- When stripping the enameled coating, use appropriate tools to avoid damaging the wire itself.

- Consider the gauge of wire you need based on the load requirements of your project, as this can impact both efficiency and safety.

Enameled copper wire is renowned for its exceptional durability and longevity, making it a preferred choice for a variety of electrical projects. The enameled coating on the wire not only provides insulation but also protects against environmental factors such as moisture, dust, and corrosive elements. This added layer of protection significantly reduces the risk of short circuits and electrical failures, ensuring that your projects maintain their integrity over time.

Furthermore, the longevity of enameled copper wire is highlighted by its resistance to wear and tear. Unlike bare copper wires, which can oxidize and deteriorate when exposed to air and moisture, enameled wires resist these challenges effectively. This characteristic means that projects utilizing enameled copper wire can operate efficiently for extended periods without the need for frequent maintenance or replacements. As a result, investing in enameled copper wire not only enhances the reliability of your electrical systems but also contributes to overall cost-effectiveness in the long run.

| Feature | Enameled Copper Wire | Bare Copper Wire |

|---|---|---|

| Durability | High resistance to corrosion and wear | Prone to oxidation and deterioration |

| Temperature Resistance | Can withstand higher temperatures | Limited temperature tolerance |

| Insulation | Enameled coating provides excellent insulation | Requires separate insulation |

| Weight | Lighter due to thin coating | Heavier due to thicker gauge |

| Flexibility | More flexible and easier to handle | Less flexible |

| Applications | Ideal for motors, transformers, and electronics | Common in general wiring |

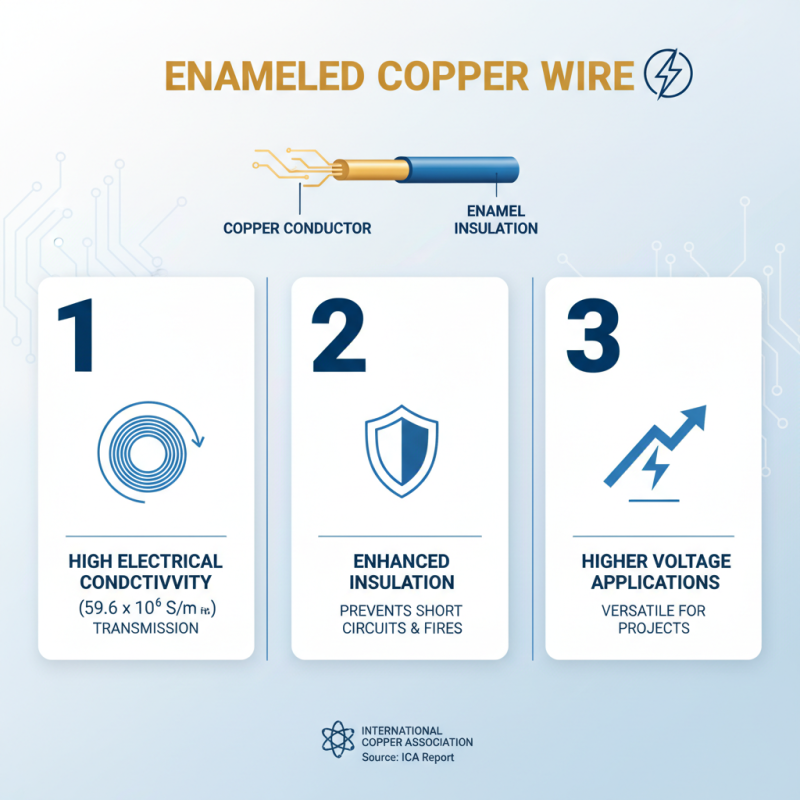

Enameled copper wire has gained immense popularity in various electrical projects due to its remarkable electrical conductivity. According to a report by the International Copper Association, copper's electrical conductivity is approximately 59.6 x 10^6 S/m, making it one of the best choices for efficient electrical transmission. The enameled coating on copper wire not only enhances its conductivity but also provides significant insulation, enabling it to handle higher voltage applications without the risk of short circuits or electrical fires.

Moreover, the enameled layer protects the copper wire from environmental factors such as moisture and corrosion, which can severely impact electrical performance. A study by the IEEE (Institute of Electrical and Electronics Engineers) highlights that enameled copper wire maintains optimal conductivity levels even under challenging conditions, with minimal resistance increase over time. This durability extends the lifespan of electrical systems, showing that projects utilizing enameled copper wire can expect lower maintenance costs and increased reliability. By combining excellent conductivity with robust protection, enameled copper wire remains a preferred choice for both small-scale and large-scale electrical applications.

When considering electrical projects, choosing the appropriate type of wire is crucial for both performance and durability. Enameled copper wire, with its insulated coating, offers several advantages over non-coating alternatives. The insulation not only protects the copper from oxidation but also enhances electrical transmission efficiency. According to industry reports, enameled copper wire can reduce energy loss by up to 30% compared to bare copper wire. This makes it an ideal choice for applications requiring high electrical performance, such as in motors, transformers, and electronic devices.

In contrast, non-coating alternatives, such as bare copper wire, are more susceptible to environmental factors like moisture and corrosion, potentially leading to higher maintenance costs and reduced lifespan. A study conducted by the Institute of Electrical and Electronics Engineers (IEEE) highlights that wires without proper insulation experience a significant increase in resistance over time, which can compromise performance and safety. Furthermore, the enameled coating significantly diminishes the risk of short circuits by providing a robust barrier against accidental contact. Overall, the durability and efficiency of enameled copper wire make it a superior choice in a wide range of electrical applications.

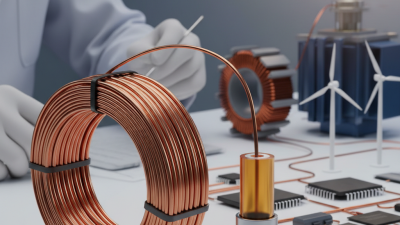

Enameled copper wire is widely utilized in various electrical systems due to its outstanding properties. One of the primary applications is in the manufacture of transformers. The enameled coating provides electrical insulation, allowing for tight winding of coils without the risk of short circuits. This is essential in transformers, which require efficient energy conversion from one voltage level to another without interference.

Another critical application of enameled copper wire is in electric motors. The insulated wire enables the creation of strong magnetic fields while minimizing energy loss due to electrical resistance. In motor windings, the enameled layer helps sustain high operational temperatures, enhancing longevity and reliability. Furthermore, it plays a vital role in reducing noise, producing smoother operation, which is especially advantageous in consumer appliances.

In addition, enameled copper wire finds significant use in inductor and solenoid designs, where precise control of current flow is necessary. The insulation by the enamel prevents unwanted electromagnetic interference, ensuring a focused magnetic field. This feature is particularly important in radio frequency applications, where performance depends heavily on the stability and precision of electrical signals.