Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving landscape of manufacturing and construction, the choice of materials plays a crucial role in the success of various projects. Among these materials, Soft Coated Wire has gained significant attention for its versatility and durability. According to a recent industry report by Global Wire Solutions, the demand for Soft Coated Wire is projected to grow by 8% annually through 2025, driven by its applications in sectors such as automotive, electronics, and construction. This growth is indicative of the increasing recognition of Soft Coated Wire as a reliable choice for a wide array of projects.

As industry expert Dr. Emily Richards emphasizes, "The advancements in coating technology have greatly enhanced the performance of Soft Coated Wire, making it an essential component in modern engineering." Her insights highlight the importance of selecting the right type of wire for specific applications to ensure optimal results. In this article, we will explore the best Soft Coated Wire options available in 2023, discussing their benefits, applications, and how they can contribute to the success of your projects. With the constant innovation within this field, understanding the various options can empower professionals to make informed decisions that enhance the performance and longevity of their work.

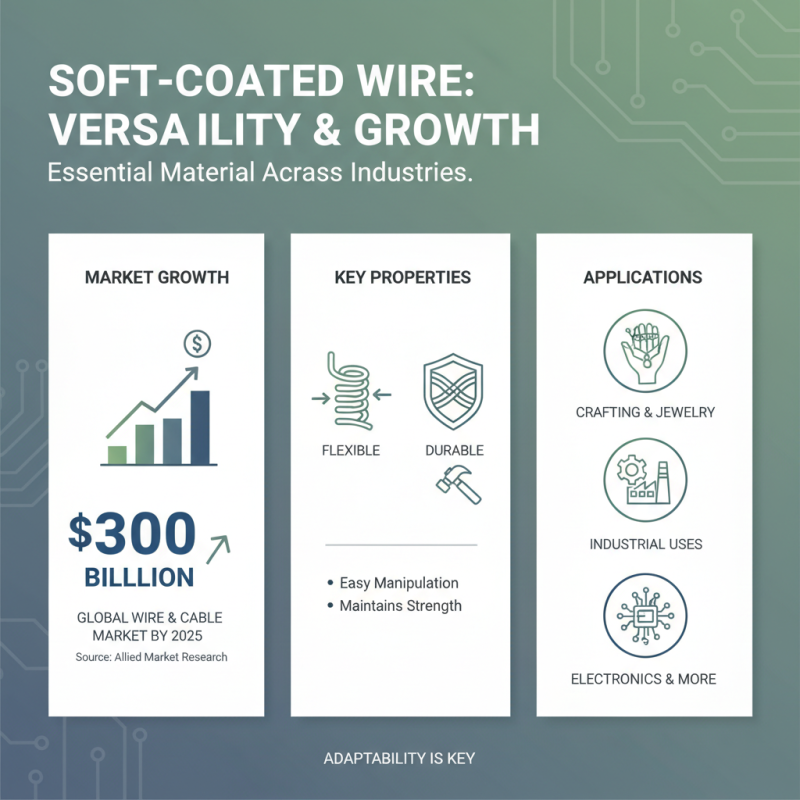

Soft coated wire has become an essential material in various projects due to its versatility and unique properties. According to a report by Allied Market Research, the global wire and cable market is projected to reach $300 billion by 2025, driven largely by increased demand for insulated wires like soft coated options. These wires are favored for their flexible yet durable nature, allowing for easy manipulation without sacrificing strength. This makes them ideal for applications ranging from crafting and jewelry making to industrial uses, where adaptability is key.

In 2023, the benefits of using soft coated wire extend beyond mere flexibility. The insulating layer around the wire significantly reduces the risk of corrosion and ensures longevity even in challenging environments. Market research by Technavio suggests that the construction sector is increasingly utilizing soft coated wire for electrical installations due to its safety features. Enhanced conductivity, lower resistance, and immunity to harsh weather conditions make it a go-to choice for builders and manufacturers alike. As industries continue to evolve, the applications of soft coated wire are expected to expand, presenting new opportunities for innovation in product design and engineering.

When selecting soft coated wire for various projects, several key characteristics should be taken into account to ensure optimal performance. Firstly, flexibility is a crucial attribute. Soft coated wire should have sufficient pliability to allow for easy shaping and manipulation without compromising its structural integrity. This flexibility makes it ideal for a variety of applications ranging from crafts and jewelry making to construction and automotive uses.

Another important characteristic is durability. The wire should be resistant to corrosion and wear, ensuring that it maintains its quality even when exposed to different environmental conditions. A coating that offers protection from rust and other forms of degradation is essential for the longevity of the wire. Additionally, the thickness of the wire plays a significant role in its strength and weight-bearing capacity. Choosing the right gauge ensures that the wire can support the intended loads without breaking or bending.

Lastly, the ease of use is an important factor. A quality soft coated wire should be easy to cut, twist, and connect, allowing for seamless integration into projects. Whether you are a hobbyist or a professional, selecting wire that combines flexibility, durability, and user-friendliness will enhance your overall project experience and outcome.

When selecting the best soft coated wire for your projects in 2023, it’s essential to analyze the various options available in the market to make an informed decision. Different brands offer unique features and benefits that cater to a wide range of applications, from crafting to industrial use. Factors such as flexibility, durability, and ease of handling are crucial when comparing products, as they directly influence the performance and user experience. Evaluating the thickness and coating materials can further help in understanding how well a wire will perform under specific conditions.

In this comparative analysis, attention should be given to product specifications and customer reviews, as they provide valuable insights into real-world usability. Some brands may excel in providing a softer touch and greater pliability suitable for delicate projects, while others might focus on enhanced strength and resistance to corrosion. Additionally, packaging options and lengths offered can affect project efficiency, with bulk purchases often serving as cost-effective solutions for larger-scale tasks. Thus, understanding these differences allows users to select the ideal soft coated wire tailored to their individual project requirements.

When considering soft coated wire options for various projects in 2023, it’s essential to focus not only on their functionality but also their environmental impact and sustainability. Soft coated wires, typically made from materials that may include eco-friendly polymers or recycled metals, present an opportunity to reduce waste and lower the carbon footprint in manufacturing processes. By selecting wires that adhere to sustainable practices, consumers can contribute to a more responsible production cycle while still achieving reliable performance in their projects.

Another key aspect of sustainability in soft coated wire selection involves the recycling potential of the materials used. Wires that are easy to recycle at the end of their life cycle can significantly mitigate the amount of waste sent to landfills. Additionally, the production of soft coated wires can be optimized to minimize energy consumption, further reducing their environmental impact. As awareness of ecological issues grows, choosing products that prioritize sustainability becomes a crucial aspect of responsible consumption, ensuring that projects not only meet aesthetic and functional needs but also support a healthier planet.

| Wire Type | Material Composition | Environmental Rating | Recyclability | Typical Applications |

|---|---|---|---|---|

| PVC Coated Wire | Steel core with PVC coating | Low Impact | Yes | Fencing, gardening |

| Polyester Coated Wire | Steel core with polyester coating | Moderate Impact | Yes | Industrial applications, art projects |

| Nylon Coated Wire | Steel core with nylon coating | Low Impact | Yes | Electrical projects, crafting |

| Galvanized Wire | Galvanized steel | Moderate Impact | Yes | Construction, agriculture |

| Eco-Friendly Wire | Biodegradable coating on steel | High Impact | Yes | Sustainable projects |

In 2023, the demand for soft coated wire solutions has surged, driven by various industries seeking cost-efficiency without compromising on performance. According to a report by Markets and Markets, the global wire and cable market is projected to reach $225 billion by 2025, with soft coated wire making up a significant portion of this growth. This type of wire is favored for its flexibility, corrosion resistance, and lightweight properties, making it an ideal choice for applications ranging from construction to arts and crafts.

Cost-efficiency is crucial in project planning, and the performance metrics of soft coated wire support its favorable position in the market. Data from a recent industry analysis suggests that soft coated wire offers better tensile strength compared to regular wire, providing an average stiffness-to-weight ratio improvement of about 15%. Furthermore, the lower maintenance costs associated with its corrosion resistance can lead to substantial savings over time. For businesses aiming to balance performance and budget, selecting soft coated wire can be a strategic decision that enhances overall project outcomes while maintaining financial viability.