Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In today’s rapidly evolving technological landscape, materials that combine durability with efficiency are more important than ever. One such material taking the spotlight is varnished copper. Known for its superior conductivity and resistance to corrosion, varnished copper has emerged as a preferred choice in various modern applications, from electrical components to decorative elements in design. This unique combination of properties not only enhances performance but also contributes to the longevity of products, making it a valuable asset in multiple industries.

The significance of varnished copper extends beyond its functional benefits; it also offers aesthetic advantages that appeal to designers and engineers alike. With the ability to retain its visual appeal while providing functional integrity, varnished copper proves to be a versatile material capable of meeting the demands of contemporary applications. In this article, we will explore the top five benefits of using varnished copper, highlighting why it has become an essential material in modern innovation and design. Whether you are in manufacturing, construction, or the arts, understanding these advantages could influence your choice of materials in future projects.

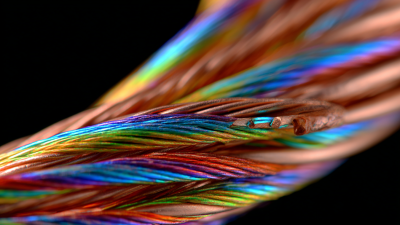

Varnished copper has emerged as a preferred material in electrical wiring solutions due to its enhanced properties that outperform traditional materials. One of the primary advantages is its superior corrosion resistance. According to a report by the International Copper Association, varnished copper wires exhibit a lifespan extension of up to 30% in harsh environments compared to non-varnished options. This durability is especially beneficial in applications like industrial machinery and outdoor installations, where exposure to moisture and pollutants can significantly impact performance.

Varnished copper has emerged as a preferred material in electrical wiring solutions due to its enhanced properties that outperform traditional materials. One of the primary advantages is its superior corrosion resistance. According to a report by the International Copper Association, varnished copper wires exhibit a lifespan extension of up to 30% in harsh environments compared to non-varnished options. This durability is especially beneficial in applications like industrial machinery and outdoor installations, where exposure to moisture and pollutants can significantly impact performance.

In addition, varnished copper demonstrates improved electrical conductivity while minimizing oxidation. The insulating varnish acts as a protective barrier, ensuring that the copper remains efficient in conducting electricity. Data from the Electrical Manufacturing Association indicates that varnished copper wires can achieve conductivity levels over 99%, thus enhancing energy efficiency in various applications, from residential wiring to sophisticated aerospace systems. The combination of durability, efficiency, and reliability positions varnished copper as an ideal choice for modern electrical engineering projects.

Varnished copper has become increasingly popular in modern applications due to its enhanced durability, particularly in harsh environments. The varnish coating adds an extra layer of protection, shielding the copper from moisture, corrosion, and oxidation. This makes varnished copper an ideal material for outdoor projects, electrical components, and architectural designs where traditional copper might fail over time. The longevity of varnished copper not only extends the life of these applications but also reduces maintenance costs for businesses and homeowners alike.

When using varnished copper, consider the environment where it will be installed. Areas with high humidity or exposure to chemicals may require a thicker varnish for optimal protection. Additionally, ensure that the surface is clean and dry before applying the varnish to enhance adhesion and durability. Regular inspections of varnished copper installations can help identify any wear or damage, allowing for timely repairs and ensuring that its benefits are fully realized.

One of the key advantages of varnished copper is its aesthetic appeal. Its warm, rich hue complements a variety of designs, making it a versatile choice for both functional and decorative applications. To maintain its appearance, avoid abrasive cleaning materials that can scratch the varnish. Instead, use a soft cloth and mild detergent to keep the surface looking pristine while benefiting from varnished copper's resilience in challenging conditions.

Varnished copper has emerged as a vital material in various modern applications, particularly in heat exchangers where thermal efficiency is paramount. The varnishing process enhances the copper's natural properties, providing a protective layer that minimizes oxidation and corrosion. This preservation not only extends the lifespan of components but also ensures consistent thermal conductivity, which is crucial for efficient heat transfer. As heat exchangers play a pivotal role in numerous industrial processes, the utilization of varnished copper significantly optimizes energy consumption and operational performance.

Moreover, the thermal efficiency benefits of varnished copper are notable in energy recovery systems and HVAC applications. The smooth, varnished surface reduces fouling, allowing for better heat exchange rates and lower pressure drops. This reduction in resistance contributes to improved overall system efficiency and lowers maintenance costs, as the need for cleaning and repairs diminishes. In energy-conscious industries, the adoption of varnished copper is not just an enhancement; it represents a commitment to sustainability and operational excellence.

| Benefit | Description | Impact on Thermal Efficiency |

|---|---|---|

| Higher Thermal Conductivity | Varnished copper provides excellent thermal conductivity for efficient heat exchange. | Improves heat transfer rates, leading to better performance in heaters and coolers. |

| Corrosion Resistance | Varnished finish protects copper from corrosion and oxidation. | Increases longevity of heat exchangers, thus maintaining efficiency over time. |

| Reduced Maintenance Costs | Less frequent need for repairs or replacements due to enhanced durability. | Sustains operational efficiency while lowering overall costs. |

| Improved Aesthetics | The varnished finish provides a clean and polished appearance. | Enhances product appeal, important for consumer-facing applications. |

| Versatility | Can be used in various industrial applications beyond heat exchangers. | Broadens application scope, making it suitable for varied thermal systems. |

| Lightweight | Copper is lighter than many other metals used for heat exchangers. | Facilitates easier handling and installation, reducing labor costs. |

| Recyclability | Copper is a recyclable material, promoting sustainability. | Supports circular economy practices in manufacturing sectors. |

| Thermal Stability | Maintains performance across a range of temperatures. | Ensures consistent efficiency in variable operating conditions. |

| Low Thermal Expansion | Copper has low expansion properties, reducing stress on fittings. | Increases reliability of the system under thermal cycling conditions. |

| Enhanced Efficiency Ratings | Improves overall efficiency ratings in applications with heat exchangers. | Promotes better energy use and sustainability in industrial systems. |

Varnished copper has gained popularity in modern applications, particularly due to its striking aesthetic appeal. The glossy finish of varnished copper not only catches the eye but also adds a touch of sophistication to various settings. This distinctive appearance makes it an ideal choice for decorative elements in architecture, interior design, and various art installations, allowing designers to create visually stunning environments that stand out.

Varnished copper is rapidly gaining popularity in modern design, not only for its aesthetic appeal but also for its sustainability and recyclability. As designers and manufacturers become more conscious of their environmental impact, varnished copper stands out due to its longevity. The coating protects the copper from tarnishing, thereby extending its lifespan and minimizing waste. This durability means less frequent replacements, leading to reduced resource consumption and a lower carbon footprint.

When considering varnished copper for your projects, one tip is to ensure that you're sourcing your materials from suppliers who prioritize eco-friendly practices. Look for vendors who provide information about the sourcing and production processes of their varnished copper. This can help you choose materials that align with your sustainability goals.

Additionally, remember that varnished copper can be fully recycled at the end of its life cycle. This provides an opportunity for circular design, where the materials can be reclaimed and repurposed. Incorporating varnished copper in your designs not only enhances the visual appeal but also contributes to a more sustainable future. By making thoughtful choices in material selection, you can play a role in promoting a greener planet.