Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

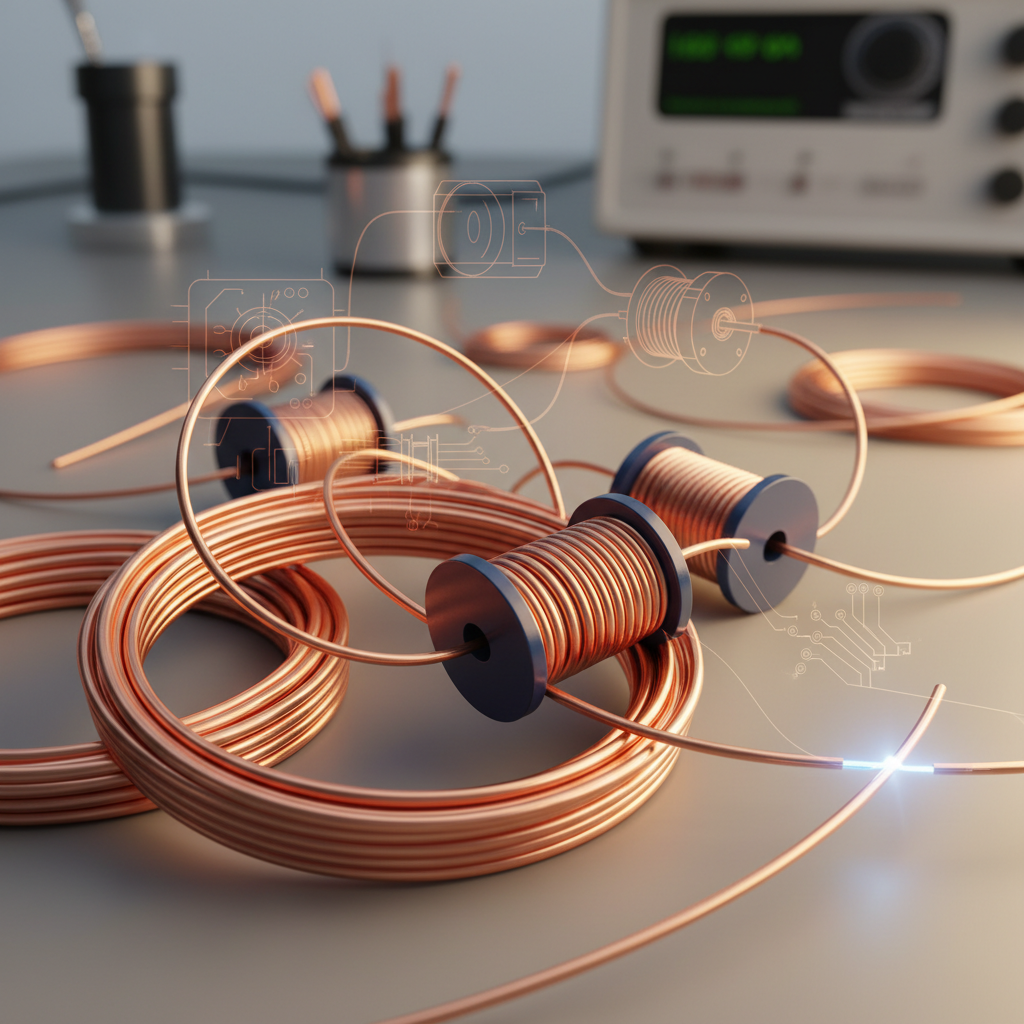

In the rapidly advancing world of electrical engineering, the significance of Enameled Magnet Wire cannot be overstated. As emphasized by industry expert Dr. Emily Johnson, a leading researcher in electromagnetic materials, “Enameled Magnet Wire is the backbone of modern electrical applications, providing both efficiency and reliability.” This innovative material is not only essential for traditional motor windings but has become increasingly critical in the development of new technologies.

As we explore the top 10 benefits of Enameled Magnet Wire, it becomes clear how integral this component is in enhancing performance across various electrical applications. Its unique properties, such as improved thermal resistance, high dielectric strength, and exceptional corrosion protection, make it the preferred choice for manufacturers and engineers alike. With advancements in insulation technology and materials science, Enameled Magnet Wire continues to evolve, paving the way for more efficient and durable electrical systems. In the following sections, we will delve deeper into these benefits, shedding light on why Enameled Magnet Wire is indispensable for the future of electrical applications.

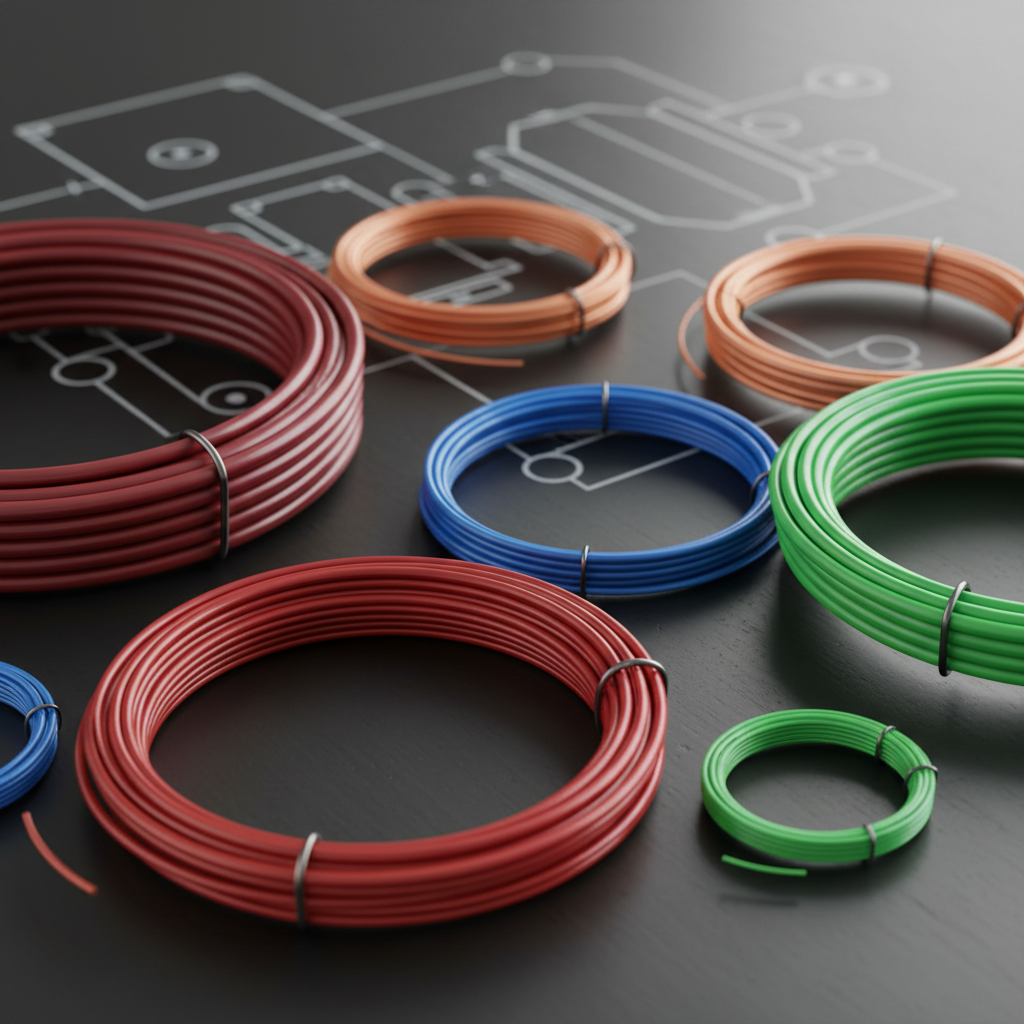

Enameled magnet wire, commonly used in various electrical applications, offers distinct advantages that enhance functionality and efficiency. One of the primary benefits is its excellent insulation properties, which prevent electrical shorts and enable safer operation in devices such as motors and transformers. The enamel coating ensures that the wire can withstand higher temperatures, thus extending the lifespan of the components and reducing maintenance costs.

Another significant advantage of enameled magnet wire is its high conductivity, which ensures minimal energy loss during operation. This feature is essential in applications where energy efficiency is a priority, such as in electric vehicles and renewable energy systems. Additionally, thanks to its compact design, enameled magnet wire allows for the creation of smaller and more efficient coils, contributing to overall space savings in electrical devices. These attributes make enameled magnet wire a preferred choice for manufacturers looking to improve the performance and durability of their electrical products.

Enameled magnet wire has gained significant recognition in electrical applications, particularly due to its enhanced insulation properties. The enamel coating provides superior electrical insulation, ensuring that the wire can handle much higher voltages without risk of arcing or short circuits. According to a report published by the International Electrotechnical Commission (IEC), wires with enamel insulation can sustain up to 2-3 times higher dielectric strength compared to traditional insulated wires. This makes them ideal for use in motors, transformers, and other electrical devices where reliability and safety are paramount.

Moreover, the insulation properties of enameled magnet wire contribute to improved efficiency in electrical applications. A study by the American Institute of Physics noted that the reduced risk of electrical losses due to better insulation can lead to a 5-10% increase in overall system efficiency. Additionally, the enamel coating protects the wire from environmental factors such as moisture and chemicals, prolonging its lifespan. This is particularly vital in industries where equipment is subjected to harsh conditions, underscoring the importance of choosing enameled magnet wire for a variety of electrical applications.

Enameled magnet wire has transformed the landscape of electrical applications, particularly in electric motors, by significantly enhancing their durability and longevity. The insulation provided by the enamel coating ensures that the wire is well-protected against mechanical wear and thermal stress. This is particularly crucial in electric motors, where high temperatures and vibrations are common, leading to potential wire degradation over time. The robust nature of the enamel insulation means that motors can operate at higher temperatures without compromising performance, thus extending their service life.

Furthermore, the longevity afforded by enameled magnet wire reduces the frequency of maintenance and replacements in electrical systems. With traditional wiring, failures often necessitate extensive repairs, which can be costly and time-consuming. However, the enhanced durability of enameled magnet wire minimizes such disruptions, ensuring that electric motors can maintain efficient performance for extended periods. This reliability not only contributes to operational efficiency but also lowers overall costs related to repairs and replacements, making enameled magnet wire a preferred choice in modern electrical applications.

| Benefit | Description | Impact on Performance |

|---|---|---|

| Enhanced Insulation | Provides superior resistance to electrical erosion. | Reduces short-circuit risks, leading to safer operation. |

| Heat Resistance | Withstands higher temperatures than standard wire. | Longevity of motor components significantly improved. |

| Corrosion Resistance | Protected against environmental factors and oxidation. | Increases lifespan, particularly in harsh environments. |

| Improved Conductivity | Higher conductivity allows for efficient power transfer. | Enhances overall efficiency of electric motors. |

| Flexibility | Easily shaped to fit different motor configurations. | Facilitates quicker assembly and maintenance. |

| Low Thermal Expansion | Minimizes changes in dimensions with temperature fluctuations. | Maintains consistent performance; reduces wear. |

| Cost-Effective | Longer lifespan reduces replacement frequencies. | Lower overall maintenance costs for electric motors. |

| Improved Thermal Dissipation | Efficient heat dissipation prevents overheating. | Enhances reliability of motor performance over time. |

| Compatibility with Various Coatings | Works well with different insulation finishes. | Increases versatility in motor design applications. |

| Higher Efficiency | Promotes reduced energy loss during operation. | Results in better overall performance metrics. |

Enameled magnet wire is distinguished by its exceptional heat resistance, making it a preferred choice for various electrical applications. The enamel coating provides an insulating layer that can withstand high temperatures, ensuring the wire remains functional even under intense operating conditions. This heat resistance is critical in preventing overheating, which can lead to insulation breakdown and catastrophic equipment failures. As electrical devices become more compact and subsequently run hotter, the ability of enameled magnet wire to endure elevated temperatures without loss of performance has become indispensable.

Furthermore, the performance benefits of enameled magnet wire extend beyond its thermal endurance. It maintains excellent conductivity while minimizing energy loss, which is essential for efficiency in motors, transformers, and other electrical systems. The wire’s ability to resist corrosion and moisture further contributes to its longevity and reliability, reducing the need for frequent replacements. These characteristics not only enhance the overall lifespan of electrical components but also improve their operational efficiency, making enameled magnet wire a valuable asset in modern electrical engineering.

Enameled magnet wire is increasingly recognized for its cost-effectiveness in various electrical manufacturing processes. According to a recent market research report by Mordor Intelligence, the global enameled wire market is projected to grow at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2026. This growth is partly attributed to the high thermal efficiency and compact design that enameled wire provides, which reduces production costs for manufacturers. With lower material waste and less insulation required, companies can significantly enhance their profitability while ensuring compliance with stringent electrical standards.

Moreover, the durability and reliability of enameled magnet wire further add to its economic advantages. A study from Freedonia Group forecasts that the rising demand for electric motors and transformers will lead to increased usage of enameled wire, as its insulation properties allow for longer operational lifetimes and reduced maintenance costs. The initial investment in enameled magnet wire pays off through lower operational and replacement expenses over time. This makes it an appealing choice for manufacturers aiming to optimize their resources without compromising on quality.