Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

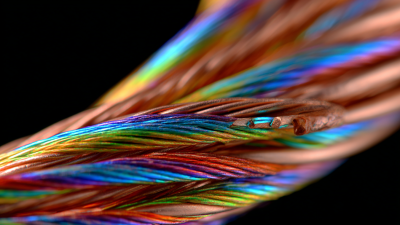

In the rapidly evolving world of electronics, the choice of materials used in manufacturing plays a crucial role in the performance and longevity of devices. One particularly noteworthy option is copper wire with enameled coating, which offers a range of advantages that enhance both electrical efficiency and durability. This specialized form of copper wire combines the excellent conductivity of copper with the protective qualities of an insulating enamel coating, creating a versatile solution for various applications in electronics.

The benefits of using copper wire with enameled coating extend beyond mere conductivity. The enamel coating not only protects the wire from oxidation and corrosion but also reduces the risk of short circuits, making it an essential component in modern electronic designs. Additionally, its lightweight and flexible nature allow for easier handling and installation in compact spaces, which is increasingly important as devices continue to shrink in size. As we delve into the top five benefits of this material, it becomes clear why copper wire with enameled coating is favored by engineers and designers aiming for innovation and reliability in their electronic products.

When it comes to electronics, the choice of wire materials can significantly impact performance and reliability. Copper wire, particularly with an enameled coating, offers distinct advantages in various electronic applications. The enameled coating not only improves insulation but also enhances the wire's resistance to environmental factors, thereby increasing durability. This added protection allows for better performance in high-temperature environments or situations where moisture might be a concern.

In addition to durability, the excellent conductivity of copper ensures efficient energy transfer. Fast signal transmission is crucial in electronic devices, and copper excels in maintaining a low resistance pathway. This characteristic is particularly important in applications ranging from circuit boards to transformers, where optimal performance is essential for functionality.

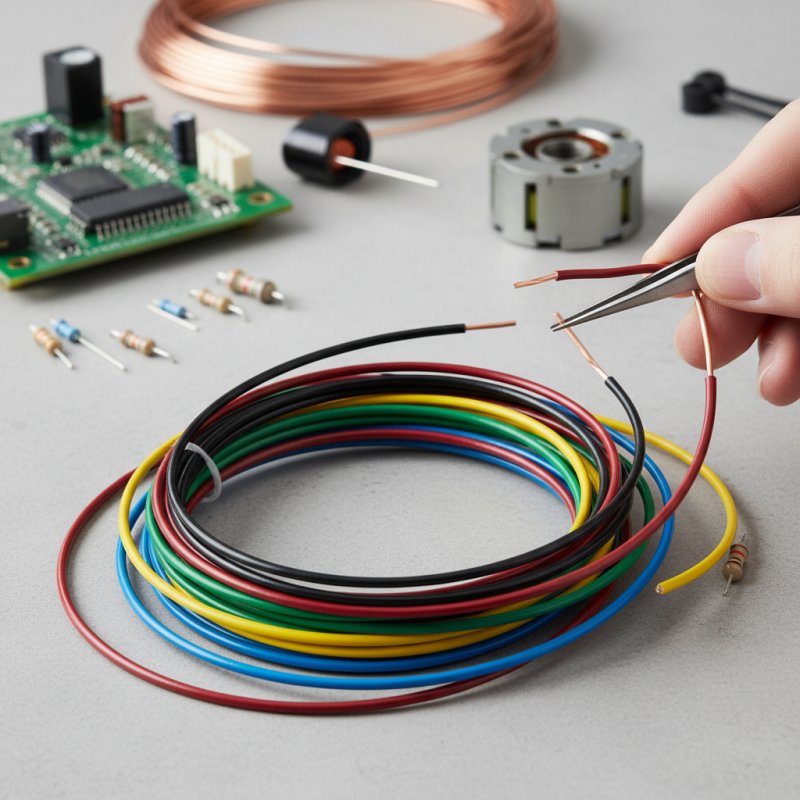

Tip: When selecting copper wire for electronics, always consider the gauge and length based on the specific requirements of your project. Using an appropriate gauge can help minimize resistance and heat generation, enhancing overall safety and efficiency. Additionally, ensure that the enameled coating is suitable for your application, as various types can offer different levels of insulation and thermal resistance.

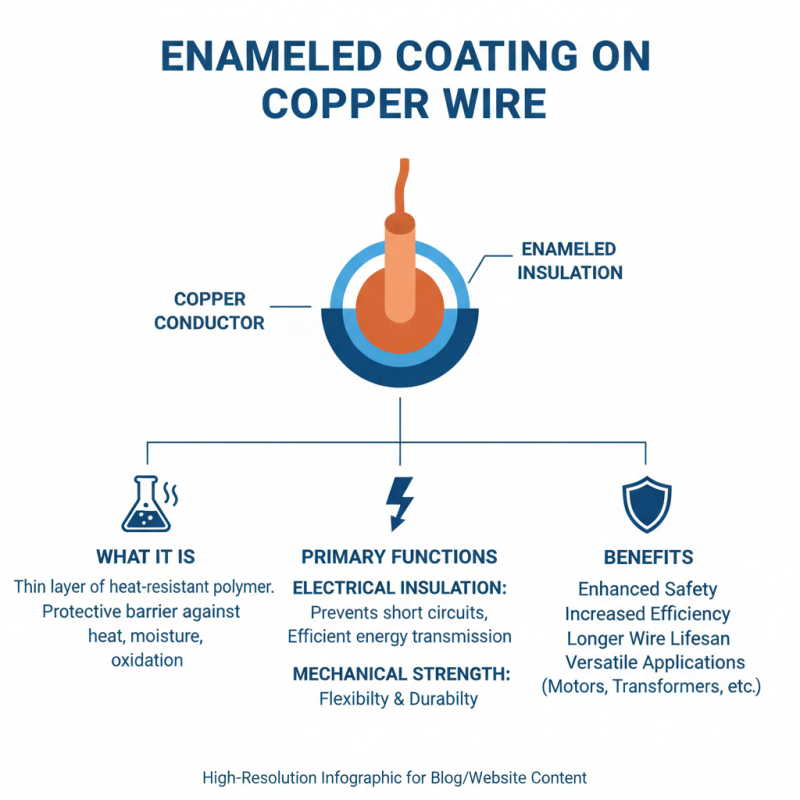

Enameled coating refers to a layer of insulation applied to copper wire, forming a protective and functional barrier. This coating is typically made from a variety of polymer materials that are heat-resistant and durable, allowing the wire to withstand heat, moisture, and oxidation. One of the primary functions of the enameled coating is to enhance electrical insulation, which helps prevent short circuits and promotes efficient energy transmission. Additionally, the enameled layer contributes to the wire’s mechanical strength, providing flexibility without compromising integrity.

When working with enameled copper wire, it’s essential to keep a few tips in mind. First, ensure you use the right tools for stripping the enamel when making connections; using inappropriate methods can damage the wire. Second, consider the environment in which the wire will be used. Enameled wire is particularly beneficial in applications where exposure to high temperatures or humidity is a concern. Finally, don’t overlook the importance of selecting the appropriate gauge for your specific project needs, as the thickness of the wire also influences performance and efficiency.

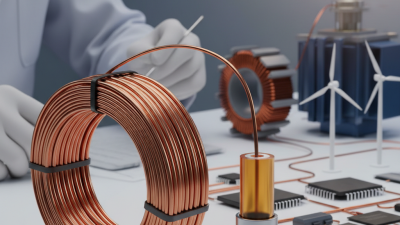

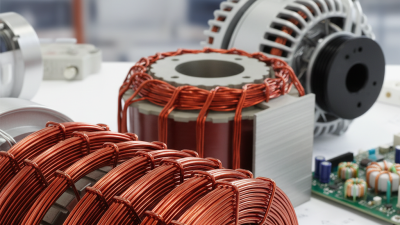

Moreover, enameled wires are widely used in the manufacturing of inductors and transformers due to their lightweight and high conductivity. The enameled coating plays a crucial role in conserving space, as it allows for tighter winding configurations without risking electrical interference. This efficiency makes it an ideal choice for contemporary electronic applications requiring performance and compactness.

Enameled copper wires have gained prominence in the electronics industry due to their enhanced durability. The enamel coating provides an insulating layer that protects the copper wire from moisture, dust, and other environmental factors that can cause corrosion. This durability ensures a longer lifespan for electronic components, reducing the frequency of replacements and maintenance. As electronic devices become smaller and more complex, the reliability of the materials used becomes paramount, making enameled copper wires an ideal choice for many applications.

Tips for maintaining the longevity of enameled copper wires include avoiding excessive bending or twisting during installation, as this can compromise the integrity of the enamel coating. Additionally, it's beneficial to use protective conduits or coverings when installing wires in exposed areas to further shield them from potential damage. Regular inspections can also help identify any signs of wear or degradation early, allowing for proactive measures to be taken to ensure optimal performance.

Moreover, selecting the right gauge of enameled copper wire for your specific application is crucial. Thicker wires may provide additional durability, but they also require careful consideration of the weight and space limitations in your design. Proper soldering techniques can also enhance the junction integrity, ensuring that the performance benefits of enameled copper wires are fully realized in your electronic projects.

Enameled copper wire is widely recognized for its superior electrical conductivity, making it a preferred material in various electronic applications. The coating of enamel serves as an insulator, preventing short circuits and ensuring that the current flows efficiently through the copper conductor. This combination of conductivity and insulation allows for tighter packing of wires in devices, facilitating more compact designs without compromising performance.

Moreover, the enameled coating adds a layer of protection against environmental factors such as moisture and corrosion, which can degrade electrical performance over time. This durability enhances the longevity of electronic components, as the wire maintains its conductive properties even under challenging conditions. Consequently, using enameled copper wire not only optimizes the functionality of electronics but also leads to reduced maintenance costs and improved reliability in performance-critical applications.

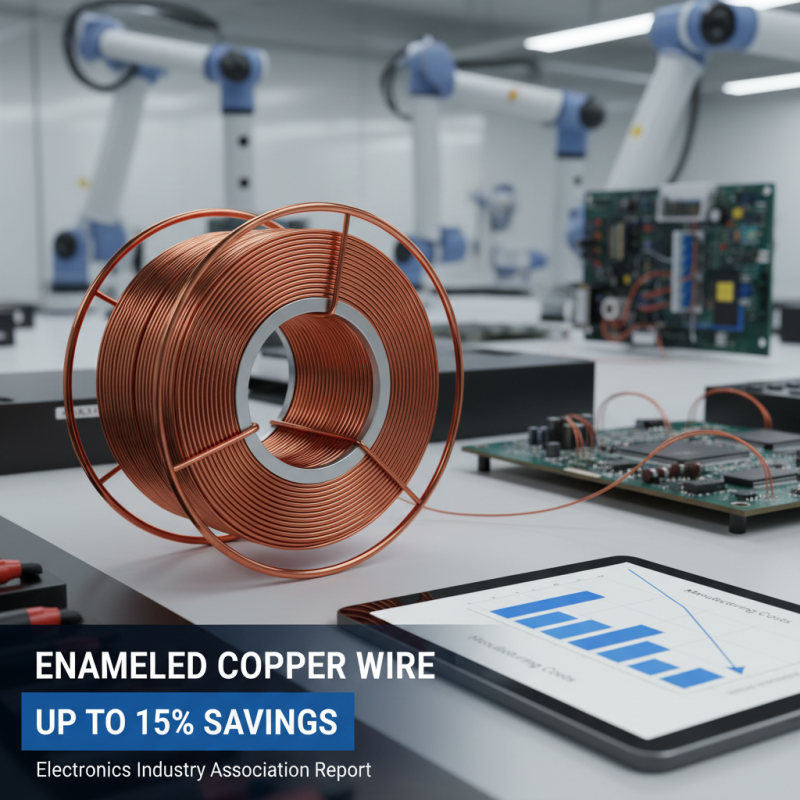

The cost-effectiveness of using enameled copper wire in manufacturing electronics is a critical consideration for industries striving to optimize their production processes while maintaining high quality. According to a report by the Electronics Industry Association, enameled copper wire can reduce overall manufacturing costs by up to 15% compared to traditional wire options. This reduction is largely attributed to the lower energy consumption during wire production and the decreased need for additional insulating materials. Manufacturers can thus achieve higher operational efficiency without sacrificing performance.

Moreover, enameled copper wire offers substantial benefits in terms of material usage. A study conducted by the Institute of Electrical and Electronics Engineers (IEEE) highlights that using enameled copper wire minimizes waste during the winding process in motors and transformers. This material's superior insulation properties lead to less space being required for coil designs, allowing manufacturers to produce more compact and lightweight electronic devices. The enhanced efficiency not only cuts costs but also contributes to sustainability efforts, aligning with the growing demand for environmentally friendly manufacturing practices. As businesses seek to balance cost and quality, enameled copper wire presents an appealing solution in the competitive electronics sector.