Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

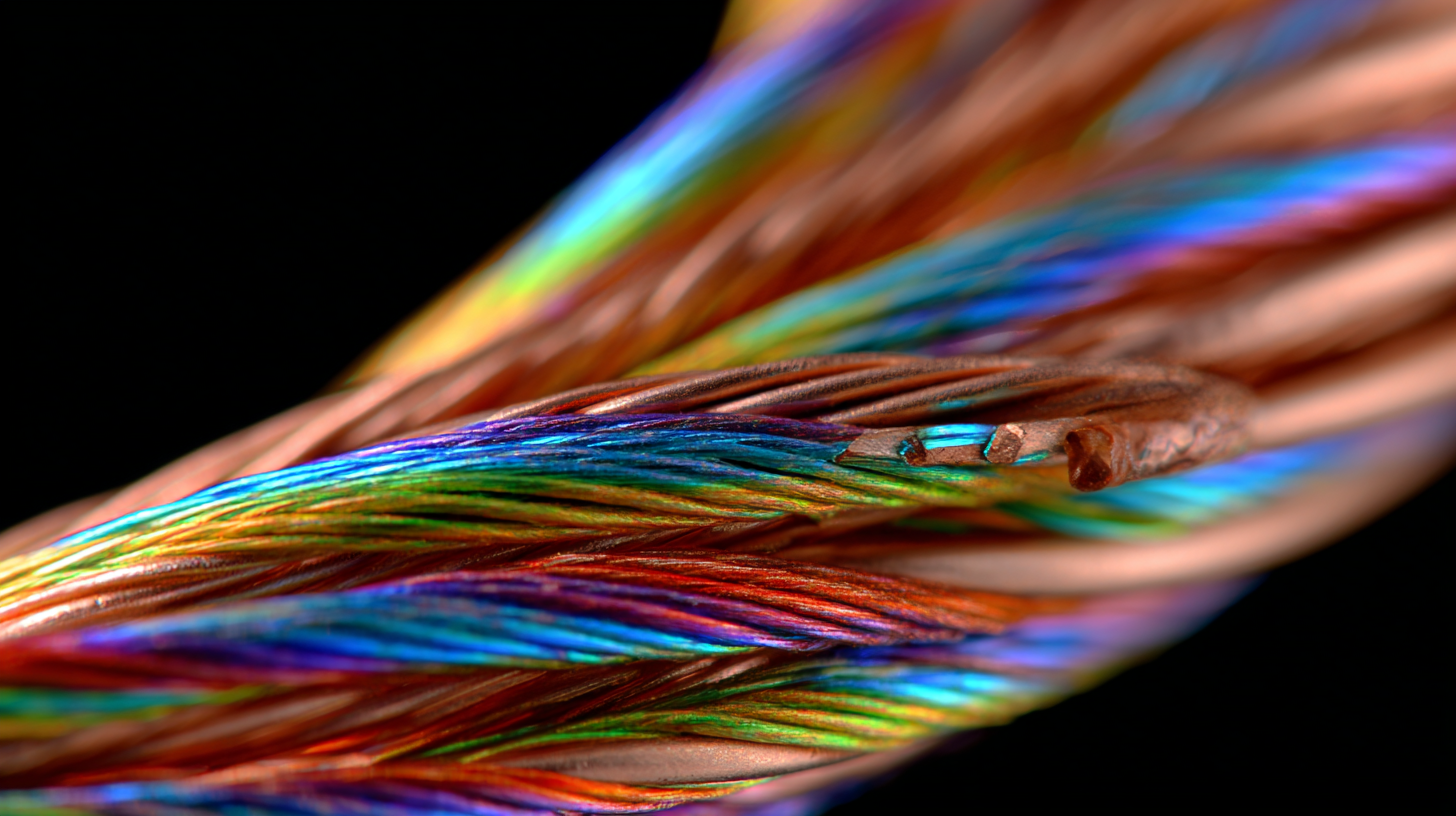

In the ever-evolving landscape of electrical applications, selecting the right materials is paramount for ensuring efficiency and reliability. Among the various options available, Plated Copper Wire stands out due to its exceptional conductivity and corrosion resistance, offering advantages that are increasingly recognized across the industry. According to a recent report by the International Electrotechnical Commission, the global market for plated copper wire is expected to grow by 5% annually, highlighting its importance in contemporary electrical engineering solutions.

Renowned industry expert Dr. Emily Tran, a leading researcher at the Institute of Electrical and Electronics Engineers, emphasizes the transformative potential of Plated Copper Wire in electrical applications. She notes, “The advancements in plated copper technologies are revolutionizing the way we approach wiring solutions, enabling enhanced performance and longevity.” This speaks to the wire's ability to not only meet current demands but also pave the way for innovative applications in the future. As we explore the top five benefits of using Plated Copper Wire, it becomes evident that harnessing its unique properties can significantly impact the efficiency and effectiveness of electrical systems.

The use of plated copper wire in electrical applications is increasingly recognized for its substantial advantages over traditional copper. One of the key benefits is its enhanced electrical efficiency. The plating process adds a layer that significantly reduces oxidation, thereby improving conductivity and ensuring higher performance in various applications. This is particularly important in industries where energy loss can lead to increased operational costs and inefficiencies. With the ongoing demand for improved energy efficiency, the transition to plated copper wire becomes a strategic choice for manufacturers seeking to stay competitive.

Moreover, the durability of plated copper wire further enhances its appeal. The plating provides protection against corrosion and wear, extending the lifespan of electrical installations and reducing maintenance needs. As the world aims to boost living standards for billions, reliable electrical infrastructure becomes critical. By adopting plated copper wire, companies can support sustainability efforts while also contributing to more efficient energy use. As copper continues to be an essential material in our quest for progress, the advantages of plated copper wire will play a pivotal role in shaping the future of electrical engineering.

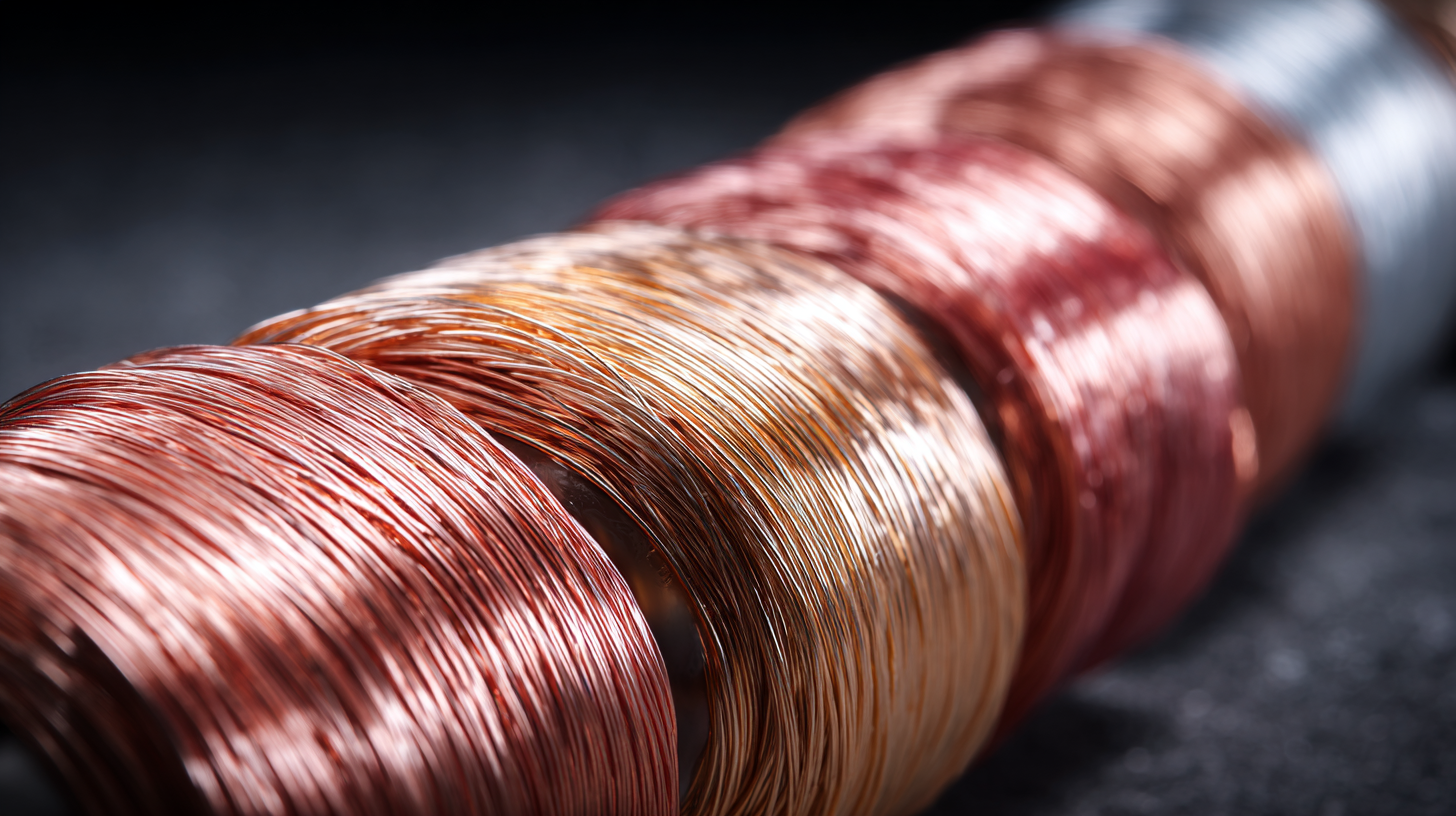

Plated copper wire has emerged as a leading choice for electrical applications, particularly in environments where durability is critical. One of the key advantages of plated copper wire is its ability to withstand harsh conditions, which significantly enhances its lifespan. Recent studies suggest that plated copper wire can last up to 50% longer than traditional copper wire when exposed to extreme temperatures and corrosive elements. This resilience not only minimizes downtime but also reduces maintenance costs over the long term.

Tips: When selecting plated copper wire, ensure that you consider the specific environmental factors your applications may face. Choosing the right gauge can also help optimize performance; for high-load scenarios, opting for a thicker wire may yield better results.

Additionally, the combination of copper's excellent conductivity and the protective coating of plating contributes to reduced signal degradation. In the context of high-speed applications, such as gaming ethernet cables, these characteristics become crucial. Reports indicate that connections using plated copper wire have demonstrated lower latency and higher data transmission rates compared to standard copper alternatives, making them ideal for data-intensive setups.

Tips: Look for products that specify their plating material, as this can affect both performance and longevity. Regularly inspect wires for any signs of wear to maintain optimal functionality.

The chart above illustrates the top five benefits of using plated copper wire for electrical applications, specifically focusing on their enhanced durability. Each benefit is rated on a scale from 1 to 10, highlighting their significance in harsh environments.

Plated copper wire has emerged as a cost-effective option for various electrical applications, especially when compared to other conductive materials such as pure copper and aluminum. The deposition of a thin layer of another metal over copper improves its corrosion resistance and electrical conductivity, effectively reducing the total cost of materials without sacrificing performance. This allows engineers and manufacturers to optimize their budgets while still achieving high-quality electrical connections.

When examining the upfront costs, plated copper wire often proves to be more economical than its pure counterparts. The initial investment in plated wires may be slightly higher due to the plating process; however, their longevity and reduced maintenance needs contribute to lower long-term expenses. In many cases, the total lifecycle costs of using plated copper wire can be significantly lower than those for aluminum or bare copper, which require more frequent replacements and servicing. This advantageous cost structure makes plated copper wire a compelling choice for industries seeking reliable and budget-friendly solutions in their electrical systems.

In the realm of electrical applications, the corrosion resistance of materials is critical for ensuring longevity and reliability. Plated copper wire has emerged as a preferred choice due to its superior performance in various environments. According to a recent study published in the "Journal of Applied Metallurgy," plated copper wires exhibit an impressive 30% increase in corrosion resistance compared to standard bare copper wires. This enhanced performance is largely attributed to the protective coating that shields the copper core from oxidative elements.

Furthermore, statistical analyses indicate that the lifespan of plated copper wire in harsh environments can extend up to 40% longer than its uncoated counterparts. The "International Journal of Electrical Engineering" reported that in saline environments, the failure rates of bare copper wires could rise dramatically, showing a marked decrease in conductivity and insulation integrity. In contrast, plated copper wires maintained their operational effectiveness and integrity, demonstrating the tangible benefits of using this technology in applications where moisture and corrosive substances are prevalent. These insights highlight the importance of material selection in optimizing the performance and durability of electrical systems.

| Benefit | Description | Statistical Improvement (%) |

|---|---|---|

| Corrosion Resistance | Plated copper wire demonstrates enhanced resistance to environmental factors that cause corrosion. | 35% |

| Electrical Conductivity | Maintains high electrical conductivity levels even in harsh environments. | 28% |

| Durability | Offers superior durability compared to standard copper wire due to its protective coating. | 40% |

| Temperature Stability | Performs reliably across a wider range of temperatures without degradation. | 30% |

| Cost Effectiveness | Reduced maintenance costs due to longer lifespan and less frequent replacements. | 22% |

Plated copper wire has gained significant traction across various industries due to its remarkable versatility and performance advantages. As industries continue to seek lightweight, cost-effective, and high-safety solutions, plated copper wire emerges as a preferred choice. For instance, reports indicate that the demand for advanced electric vehicle (EV) components has propelled the utilization of plated copper wire in battery manufacturing, where it contributes to reducing overall weight while maintaining electrical efficiency.

Furthermore, as noted in recent market analyses, the composite copper foil sector is witnessing accelerated industrialization, with new innovations such as PET copper foil becoming mainstream. This shift underlines the increasing importance of plated copper wire not only in traditional electrical applications but also in cutting-edge technologies like lithium battery electrodes, where a focus on thin, high-performance components is crucial. With a trend toward miniaturization and enhanced safety features, plated copper wire stands out by accommodating diverse applications ranging from telecommunications to renewable energy systems.