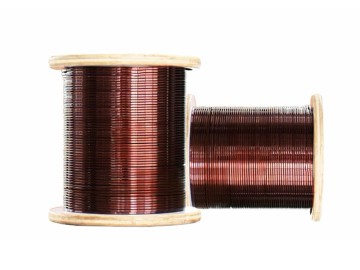

Top China Suppliers and Manufacturers of Binding Wire with Enameled Coating

As a leading supplier of Binding Wire Enameled Coated, I emphasize the importance of quality and reliability for your projects. Our wholesale offerings are tailored for businesses, providing exceptional value without sacrificing performance. With superior insulation properties and durability, our Enameled Coated binding wire is ideal for various electrical applications. I take pride in being a reputable exporter, committed to delivering materials that meet international standards through rigorous testing. By partnering with Suzhou Daiming Electrical Materials Co., Ltd., you choose a supplier dedicated to quality and customer satisfaction. Let’s discuss how our binding wire can support your upcoming projects and meet your business needs. Reach out to experience the difference of a dedicated supplier!Insider Tips For Binding Wire Enameled Coated Where Innovation Meets 2025 Guarantees Peak Performance

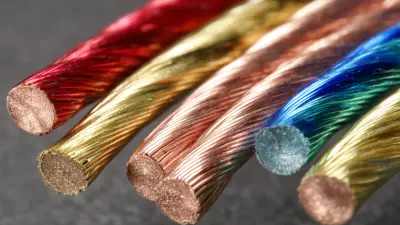

As we look ahead to 2025, the demand for high-performance enameled wires continues to rise, especially in industries that prioritize innovation and efficiency. Binding wire, enriched with a durable enameled coating, is essential for a range of applications from motors to transformers. For global buyers seeking quality and reliability, understanding the nuances of these products can make all the difference in optimizing operational performance. One of the key insider tips is to consider the wire's insulation properties. Enameled Coated Wires are designed to withstand extreme temperatures and environmental factors. When selecting a supplier, inquire about the testing certifications and standards they adhere to, ensuring that their products can perform even in the most demanding conditions. Additionally, look for manufacturers that employ advanced production technologies; this often translates to better consistency and fewer defects. Lastly, evaluating production capacity is crucial. With a strong infrastructure in place, manufacturers can provide scalable solutions tailored to your specific needs. By choosing a supplier that can meet high-volume demands without sacrificing quality, you're not only securing a reliable source but also enabling your operations to adapt to market changes swiftly. Embrace innovation and make informed purchasing decisions that guarantee peak performance in 2025 and beyond.

Insider Tips For Binding Wire Enameled Coated Where Innovation Meets 2025 Guarantees Peak Performance

| Tip Category | Description | Expected Performance | Implementation Year |

|---|---|---|---|

| Material Selection | Choose high-quality enameled coatings for durability. | Increased lifespan and resistance to wear. | 2025 |

| Coating Thickness | Optimize the coating thickness for better heat resistance. | Improved thermal performance. | 2025 |

| Application Technique | Use advanced spray techniques for uniform coating. | Consistent performance across products. | 2025 |

| Quality Control | Implement stringent quality checks during production. | Reduction in defects and increased customer satisfaction. | 2025 |

| Innovation Adoption | Stay updated with the latest coating technologies. | Enhanced product capabilities and market competitiveness. | 2025 |

Champions of Binding Wire Enameled Coated For the Current Year Factory-Direct Excellence

A

Amelia Clark

Amazing product! The after-sales team went above and beyond to ensure my satisfaction.

09 June 2025

S

Samuel Edwards

The craftsmanship is superb! Their support staff demonstrated a high level of professionalism.

16 July 2025

L

Layla Nguyen

Fantastic buy! The support staff was attentive and went above and beyond to assist me.

07 July 2025

M

Michael Johnson

Outstanding customer service! The support team was knowledgeable and responsive.

20 May 2025

J

James Anderson

The team demonstrated a high level of expertise and professionalism.

17 May 2025

A

Andrew King

Their professionalism during our correspondence was refreshing and appreciated.

23 June 2025