Best selling enameled copper clad aluminum wire for eleltromagnetic coil motors

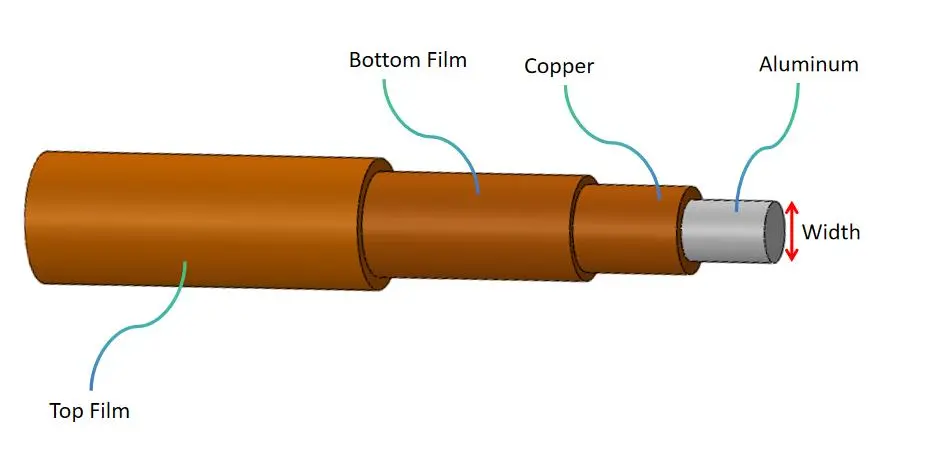

Material composition

| Type | Conductor material | Insulation layer |

| Copper clad aluminum enameled wire | Aluminum core inside, copper layer outside | Polyester, polyurethane and other paint layers |

| Enameled aluminum wire | Pure aluminum conductor | Polyester, polyurethane and other paint layers |

| Enameled copper wire | Pure copper conductor | Polyester, polyurethane and other paint layers |

Electrical performance

| Performance Indicators | Copper clad aluminum enameled wire | Enameled aluminum wire | Enameled copper wire |

| Electrical conductivity | Between copper and aluminum (about 60%~70% of pure copper) | About 61% of pure copper | High electrical conductivity (approximately 100% IACS) |

| DC resistance | Lower than enameled aluminum wire, higher than enameled copper wire | Maximum resistance (under the same cross-sectional area) | Minimum resistance |

| Current carrying capacity | Better than enameled aluminum wire, slightly lower than enameled copper wire | Minimum current carrying capacity | Maximum current carrying capacity |

| Skin Effect | Copper layer improves high frequency performance, better than pure aluminum wire | The current concentration surface is more obvious at high frequencies | Best performance at high frequencies |

Mechanical and Physical Properties

Characteristic |

Copper clad aluminum enameled wire |

Enameled aluminum wire |

Enameled copper wire |

Density |

About 2.7~3.0 g/cm³ (lower than copper, close to aluminum) |

2.7 g/cm³ (light) |

8.9 g/cm³ (weight) |

Flexibility |

Better than pure aluminum wire, close to copper wire |

Brittle, easy to break when bent |

Good flexibility, easy to process |

Antioxidant |

The copper layer can protect the aluminum core and has strong anti-oxidation ability |

Aluminum is easy to oxidize, so insulation protection needs to be strengthened |

Copper has good oxidation resistance |

Weldability |

Special process required (copper layer can be welded) |

High welding difficulty (aluminum easily forms oxide film) |

Excellent weldability |

Cost and cost Performance

| Type | Cost | Cost-effectiveness |

| Copper clad aluminum enameled wire | Lower than enameled copper wire, higher than enameled aluminum wire | Taking into account both cost and performance, suitable for medium load scenarios |

| Enameled aluminum wire | Lowest cost | Suitable for low-cost, light-load scenarios |

| Enameled copper wire | Highest cost | Best price/performance ratio for high-performance scenarios |

Application Scenarios

| Application Areas | Copper clad aluminum enameled wire | Enameled aluminum wire | Enameled copper wire |

| Power Transformer | Low-end distribution transformers | Low-end distribution transformers | High-end power transformer |

| Motor | Small and medium-sized motors (such as air conditioning compressors) | Small power motor (such as fan) | High power motor, servo motor |

| Electronic components | Inductors, chokes | Low-end coil, transformer | High frequency coils, precision components |

| Home Appliances | Refrigerator, washing machine winding | Internal circuits of some small appliances | Core components such as air conditioners and microwave ovens |

| Cable | Medium and low voltage power cables | Overhead lines, some cables | High voltage cables, precision cables |

Enameled Copper Clad Alu

Comparison of Different Product Type

Product Type |

Enameled CCA10% Copper Clad Aluminum Wire |

Enameled CCA15% Copper Clad Aluminum Wire |

Enameled CCA20% Copper Clad Aluminum Wire |

Diameter Range |

0.05mm-8.00mm |

0.05mm-8.00mm |

0.05mm-8.00mm |

DC Resistance (20°C ) |

0.0249Ω/m |

0.0249Ω/m |

0.0249Ω/m |

Conductor Density(g/cm³) |

3.32 |

3.63 |

3.94 |

Tensile Strength Nom(N/mm²) |

135 |

155 |

165 |

Elongation Nom (%) |

16 |

17 |

18 |

Conductivity (MS/m) |

35-40 |

35-42.5 |

35-45.5 |

Breakdown Voltage(>2000V) |

Non-breakdown |

Non-breakdown |

Non-breakdown |

Property |

Cost advantage over solid copper, current primarily conducted through the copper layer (skin depth <10 μm @ 1 MHz), and corrosion resistance equivalent to pure copper |

Cost advantage over solid copper, current primarily conducted through the copper layer (skin depth <10 μm @ 1 MHz), and corrosion resistance equivalent to pure copper |

Cost advantage over solid copper, current primarily conducted through the copper layer (skin depth <10 μm @ 1 MHz), and corrosion resistance equivalent to pure copper |

Application |

Transformer,Motor,Communication cables,audio equipment,electronic circuits |

Transformer,Motor,Communication cables,audio equipment,electronic circuits |

Transformer,Motor,Communication cables,audio equipment,electronic circuits |

Precautions for use USAGE NOTICE

1. Please refer to the product introduction to select the appropriate product model and specification to avoid the failure to use due to the inconsistent characteristics.

2. When receiving the goods, confirm the weight and whether the outer packing box is crushed, damaged, dented or deformed; In the process of handling, it should be handled with care to avoid vibration to make the cable fall down as a whole, resulting in no thread head, stuck wire and no smooth setting out.

3. During storage, pay attention to protection, prevent from being bruised and crushed by metal and other hard objects, and prohibit mixed storage with organic solvent, strong acid or alkali. The unused products should be wrapped tightly and stored in the original package.

4. The enameled wire should be stored in a ventilated warehouse away from dust (including metal dust). Direct sunlight is prohibited to avoid high temperature and humidity. The best storage environment is: temperature ≤50 ℃ and relative humidity ≤ 70%.

5. When removing the enameled spool, hook the right index finger and middle finger to the upper end plate hole of the reel, and hold the lower end plate with the left hand. Do not touch the enameled wire directly with your hand.

6. During the winding process, the spool should be put into the pay off cover as far as possible to avoid wire damage or solvent pollution; In the process of paying off, the winding tension should be adjusted according to the safety tension table, so as to avoid wire breakage or wire elongation caused by excessive tension, and at the same time, avoid wire contact with hard objects, resulting in paint film damage and poor short circuit.

7. Pay attention to the concentration and amount of solvent (methanol and anhydrous ethanol are recommended) when bonding the solvent bonded self-adhesive line, and pay attention to the adjustment of the distance between the hot air pipe and the mold and the temperature when bonding the hot melt bonded self-adhesive line.

Product Details

TO KNOW MORE ABOUT US, PLEASE CONTACT US!

-

daijia@dm-cable.com

-

-

Xiyang Community, Qidu Town, Wujiang District, Suzhou City, Jiangsu Province.

Our experts will solve them in no time.