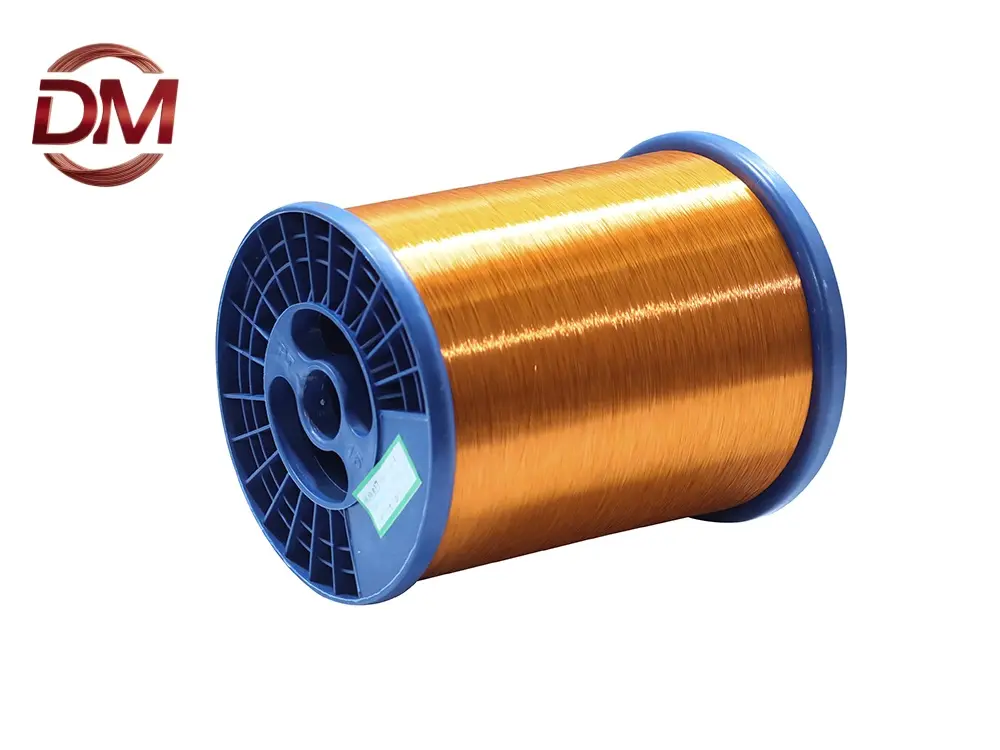

130 Class Enameled Copper Wire

Product Types

QZ/130L, PEW/130

Temperature Class(℃): B

Manufacturing Scope: 0.10mm-6.00mm, AWG 1-38, SWG 6~SWG 42

Standard: NEMA, JIS, GB/T 6109.7-2008, IEC60317-34:1997

Spool Type: PT4 - PT60, DIN250

Package of Enameled Copper Wire: Pallet Packing, Wooden case Packing

Certification: UL, SGS, ISO9001, ISO14001, accept third party inspection as well

Quality Control: company internal standard is 25% higher than IEC standard

Product Parameters

Comparison of Different Product Type | |

Product Type |

Enameled Copper Wire |

Diameter Range |

0.10mm-2.50mm |

DC Resistance (20°C ) |

0.0172Ω/m |

Conductor Density(g/cm³) |

8.96 |

Tensile Strength Nom(N/mm²) |

280 |

Elongation Nom (%) |

26 |

Conductivity (MS/m) |

56-58.5 |

Breakdown Voltage(>2000V) |

Non-breakdown |

Property |

Excellent thermal conductivity, high mechanical strength, superior compatibility,Good weldability |

Application |

Transformer, Electric Motor, Generator, Power Transmission, Specialty wires and cables, Large-scale electric motors |

Advantages of Enameled Copper Wire

1. High resistance to heat shock.

2. High temperature resistance.

3. Fit for high-speed automated routing.

4. Can be direct welding.

5. Resistant to high frequency, wearing, refrigerants and electronics corona.

6. High breakdown voltage, small dielectric loss angle.

7. Environment-friendly.

Spool & Container Weight

Packing |

Spool type |

Weight/Spool |

Maximum load quantity |

|

20GP |

40GP/ 40NOR |

|||

Pallet |

PT4 |

6.5KG |

22.5-23 tons |

22.5-23 tons |

PT10 |

15KG |

22.5-23 tons |

22.5-23 tons |

|

PT15 |

19KG |

22.5-23 tons |

22.5-23 tons |

|

PT25 |

35KG |

22.5-23 tons |

22.5-23 tons |

|

PT60 |

65KG |

22.5-23 tons |

22.5-23 tons |

|

PC400 |

80-85KG |

22.5-23 tons |

22.5-23 tons |

|

Application of 130 Class Enameled Copper Wire

enamelled wire for motor and transformer

Transformer and motor industry are large users of enamelled wire. With the development of the national economy, the increase of electricity consumption, transformer and motor demand also increase.

enamelled wire for household appliances

TV deflection coil, automobile, electric toys, electric tools, range hood, induction cooker, microwave oven, speaker equipment with power transformers and so on.

enamelled wire for automobiles

The development of the automobile industry will increase the consumption of heat-resistant special performance enamelled wire.

New enamelled wire

After the 1980s, the development of new heat-resistant enamelled wire has been turned to the study of linear structure and coating, in order to improve the performance of wire, give new functions and improve the machining performance, and develop some special cables and new enamelled wire.

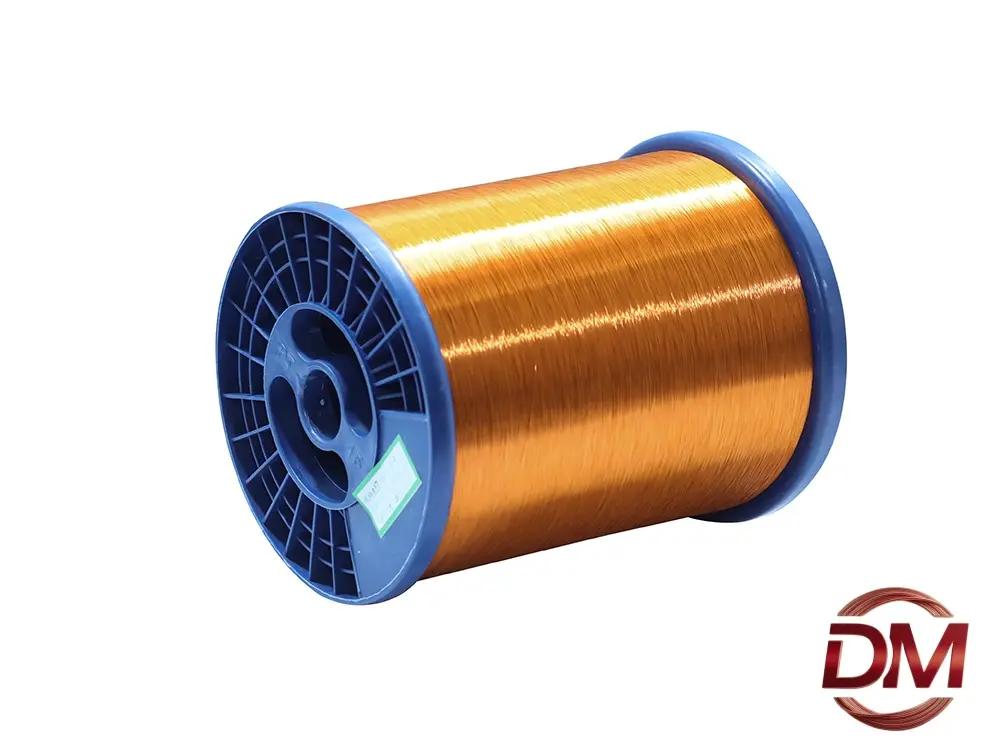

Product Details

TO KNOW MORE ABOUT US, PLEASE CONTACT US!

-

daijia@dm-cable.com

-

-

Xiyang Community, Qidu Town, Wujiang District, Suzhou City, Jiangsu Province.

Our experts will solve them in no time.